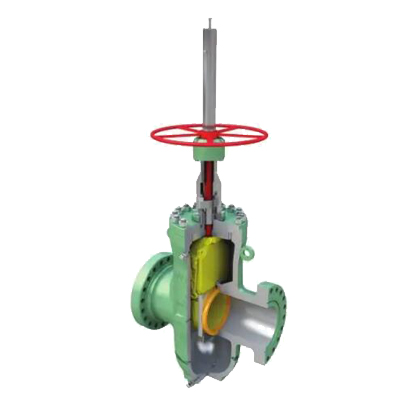

RETZ进口品质 带导流孔 无导流孔平板闸阀

简要描述:RETZ进口带导流孔,无导流孔平板闸阀是一种关闭件为平行闸板的滑动阀。其关闭件可以是单闸板或是其间带有撑开机构的双闸板。闸板向阀座的压紧力是由作用于浮动闸板或浮动阀座的介质压力来控制

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨 工况条件:开/关

工况条件:开/关 温度/压力:P-T: 160bar@120℃

温度/压力:P-T: 160bar@120℃ 更新时间:2022/11/04

更新时间:2022/11/04

(带导流孔,无导流孔)进口平板闸阀性能描述 Performance description

产品采用标准Technical Specification

设计标准Design standard:API 6D ASMEB16.34

结构长度Structuralength:API 6D ASMEB16.10

连接法兰Flanged ends:ASMEB16.5 MSS SP44,GB/T9113 JB/T79

对焊端Butt-weldingends:ASMEB16.25,GB/T 12224

试验和检验Test & inspection:API 6D ,API 598

适应温度Applicable temperature :-29~121℃

公称压力 Nominal pressure:16-16Mpa,CL150-900LB

(带导流孔,无导流孔)进口平板闸阀工作原理WorkingPrinciple

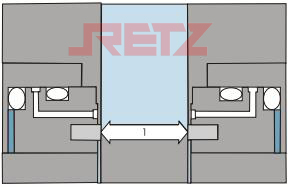

1、阀门内部压力相当时(1),闸板处于闭合状态,阀座表面PTFE密封环形成初始密封,每次阀门开或关时,阀座圈能清洁闸板两侧。(如图1)

retz With equal pressure throughout the valve(and the gate in closed position), and initial seal(1)is formed with the raised PTFE ring on the faces of the seats.(The seat-inserts clean both sides of the gate each time the valve is opened or closed)

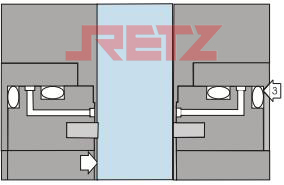

2、对阀门施加管道压力时(2),压力作用于闸板,迫使它贴近出口阀座上的PTFE环,压缩它直到闸板停在钢制阀座上,这样,就形成了双重密封,首先是PTFE对金属密封,然后是金属对金属密封,阀座也被牢固地推到凹槽,在这一点(3),O形圈阻止任何后部介质流。(如图2)

As line pressure(2)is applied to the valve. it acts on the gate, forcing it against the PTFE ring on the downstream seat,compressing it until the seat against the steel seat. Thus, a double seal is formed...first,a PTFE-to-metal seal;then, metal-to-metal. The seat is also forced firmly into its recess. The O-ring(3) prevents any downstream flow at this point.

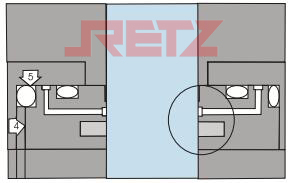

3、阀腔压力泄放后,形成进口密封,管道压力作用于进口阀座(4),使其移向闸板,这时形成PTFE对金属的密封,同时,O形圈(5)与阀座凹槽形成紧 密的密封。(如图3)retz品牌 Upstream seal is provided when valve cavity pressure is bled off. This is caused by the force of line pressure acting against the upstream seat(4)moving the seat against the gate and providing a tight PTFE-to metal seal at this point. At the same time. the O-ring(5)forms a tight seal with the seat recess.

密的密封。(如图3)retz品牌 Upstream seal is provided when valve cavity pressure is bled off. This is caused by the force of line pressure acting against the upstream seat(4)moving the seat against the gate and providing a tight PTFE-to metal seal at this point. At the same time. the O-ring(5)forms a tight seal with the seat recess.

4、阀门自动泄放多余的压力,当阀腔压力大于管道压力时,由于热膨胀,进口阀座推向凹槽,阀腔内多余的压力在阀座与闸板之间泄放到管道中。(如图4)

Valve automatically relieves itself of excessive valve cavity pressure.When valve cavity pressure exceeds line pressure..from such causes as thermal expansion..the upstream seat is forced back into its recess and the excess pressure in the valve cavity is bled between the seat and the gate into the line.

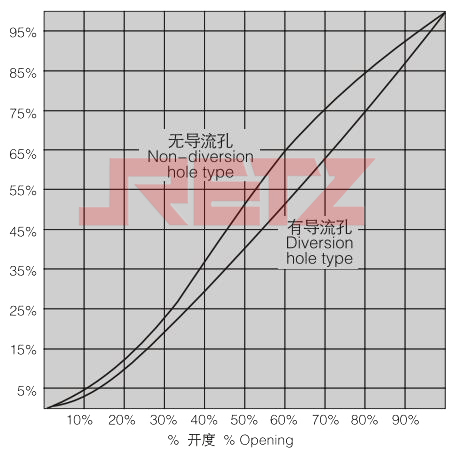

●流量特性分析Flow Charalteristic

带导流孔的平板闸阀,其流量特性等同于同规格的管道,呈等百分比特性,不带导流孔的平板闸阀,其中腔跨度较楔式闸阀小,且属于规则的圆柱体,所以,基本上除压力损失较带导流孔的大外,其余特性基本接近。不带导流孔调节型的平板闸阀其对流量的调节特性优于普通不带导流孔的平板闸阀。

The flow characteristic of flat gate valves with a diversion hole is equal to that of pipelines of thesame specification. The characteristic is shown in per centum form. As for valves without a diversion hole, its cavity fly span is smaller than that of wedge gate vales and it is a regular cylindrical object,therefore,characteristics of the valves are similar except that they have a larger pressure loss.Besides, their flux adjustment behavior is better than that of the ones with a deversion hole.

阀门开度——Cv特性曲线表Valve-opening—Cv characteristic graph

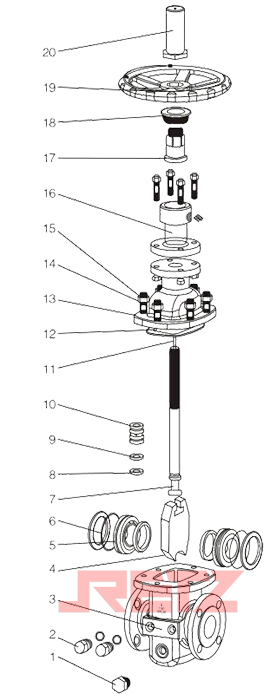

●产品结构特点Products Design Features

闸板外形图 External Drawing of Different Types of Disc

阀体有铸造和焊接两种结构。Cast and weld two structures with the body

1.阀座采用O形密封圈密封和施加预紧力的浮动阀座结构,使阀门进出口双向密封;并且该结构的启闭力矩仅为普通阀门的1/2,能到轻松开、关阀门。

The seat ring uses the floating seat ring structure with o-sealring sealed and pre-tightening force applied to have inlet and outlet dual-way sealed; and the open-close moment with this structure is 1/2 that of the common valves only, able to lightly open and close valves.

2.阀座采用密封面上镶嵌PTFE,具有PTFE对金属和金属对金属的双重密封,PTFE密封面同时清除闸板脏物的作用。

The seat ring uses the sealing face inlaid with PTFE, so has dual seals of PTFE to metal and metal to metal, the PTFE sealing face also acts as removing the dirt on the wedge disc.

3.金属对金属密封的阀门,阀体外部设有注油脂结构,油脂通过注脂器、阀座进入阀门密封面,使阀门达到零泄漏。For the valve with the metal to metal seal, there is grease injector outside of it, grease gets into the sealing face through the injector and the seat ring to have the valve up to null leak.

4.带导流孔阀门的闸板,无论是全开或是全关始终与密封面吻合,密封面得到保护不受介质直接冲刷,从而延长使用寿命。The wedge disc of the valve with flow guide hole is always fitted with the sealing face whether in full open or full close status to have the sealing face protected without being directly eroded by the medium so as to extend the duration.

5.阀门在全开时,通道平滑为直线,流阻系数极小,无压力损失,可通毛球清扫管线。

When fully opened, the valve's channel is smooth and linear, vvith an extremely small flow resisting coefficient and no pressure loss, and the pipeline can be cleaned with hair-ball through it.

6.本阀门采用带自密封能力的填料结构,无需经常调节,开、关极为轻便,且密封性可靠,填料函处设有辅助密封油脂注入结构,封性能绝对可靠,真正达到零泄漏;解决了通用阀门填料处最容易外漏的弊病。

This valve uses the packing structure with the ability of self-seal, needs no constant adjustment, features very light open and close and a reliable seal. An assisting sealing grease injection struucture is set in the packing to have the sealing performance absolutely reliable and get a true null leak, settling the problem for the oacking place of universal valves to be easiest leak outward.

7.阀门关闭时能自动卸掉内腔高压(详见工作原理图),保证使用安全。

Automatic removal of the high pressure in the internal cavity wheen the valve is about to close(see the working principle diagram for the details) so as to ensure safety.

8.全封闭结构,防护性能好,可适应全天候要求。

Fully sealed structure leaves a good protective property, suitable for the requirement of 24-hour duty.

9.阀门设有指示杆或观察窗以表示阀门的启闭情况。

An indication rod or viewing window is set with the valve to show the open-close condition.

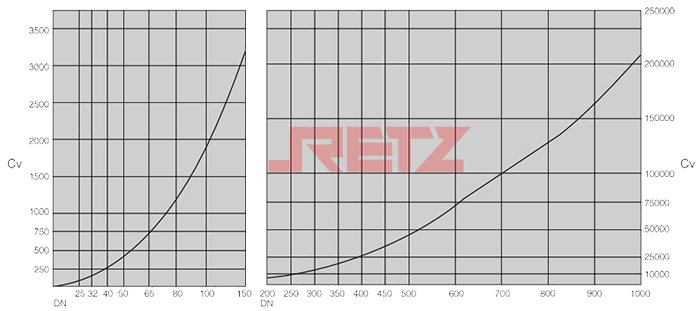

带导流孔型平板闸阀的DN—Cv曲线图 DN-Cv Graph of Flat Valves with a Diversion Hole

主要零件材料Major Parts Material Form

序号No. | 零件名称Accessory name | 材料Material | |||

普通型Ordinary type | 抗硫型Antisulphur type | ||||

GB | ASTM | GB | ASTM | ||

1 | 排污堵头Blowdown stops | 25+Zn | A105+Zn | 1Cr18Ni9 | A276-304 |

2 | 注脂接头Grease injecionjoint | 25+Zn | A105+Zn | 25+Zn | A105+Zn |

3 | 阀体Body | WCB | A216-WCB | WCB | A216-WCB |

4 | 闸板Disc | 16Mn+ENP | A105+ENP | 1Cr18Ni9 | A276-304 |

5 | 阀座Seat | 16Mn+PTFE | A105+PTFE | 1Cr18Ni9+PTFE | A276-304+PTFE |

6 | O形圈O-Ring | NBR | NBR | FPM | FPM |

7 | 阀杆Stem | 2Cr13 | A276-420 | 1Cr18Ni9 | A276-304 |

8 | 填料座Packing seat | 2Cr13 | A276-420 | 2Cr13 | A276-420 |

9 | Y型圈"Y" ring | NBR | NBR | FPM | FPM |

10 | 密封套Sealing shroud | 2Cr13 | A276-420 | 2Cr13 | A276-420 |

11 | 指示杆Indicating stem | 1Cr18Ni9 | A276-304 | 1Cr18Ni9 | A276-304 |

12 | 垫片Gasket | 柔性石墨+1Cr18Ni9Graphite+1Cr18Ni9 | 柔性石墨+304Graphite+304 | 柔性石墨+1Cr18Ni9Graphite+1Cr18Ni9 | 柔性石墨+304Graphite+304 |

13 | 阀盖Bonnet | WCB | A216-WCB | WCB | A216-WCB |

14 | 螺柱Stud | 35CrMoA | A193-B7 | 35CrMoA | A193-B7 |

15 | 螺母Nut | 45 | A194-2H | 45 | A194-2H |

16 | 支架Yoke | WCB | A216-WCB | WCB | A216-WCB |

17 | 阀杆螺母Stem nut | ZQA19-4 | C95500 | ZQA19-4 | C95500 |

18 | 压盖Gland | 25 | A105 | 25 | A105 |

19 | 手轮Hand wheel | 25 | A536-60-40-18 | 25 | A536-60-40-18 |

20 | 指示罩Indicating cover | 1Cr18Ni9 | A276-304 | 1Cr18Ni9 | A276-304 |

在线客服

在线客服