RETZ进口品质 氨用截止阀 氨气 氟利昂专用

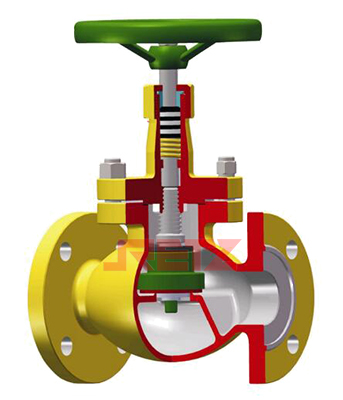

简要描述:RETZ进口氨用截止阀,氨气,氟利昂专用截至阀采用PTFE或巴氏合金制品作密封面,填料为复合软成形填料(PTFE+丁晴橡胶+弹簧),上密封也为软材 质,密封性能较好

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨 工况条件:开启/截止/节流

工况条件:开启/截止/节流 温度/压力:P-T: 40bar@120℃

温度/压力:P-T: 40bar@120℃ 更新时间:2022/11/07

更新时间:2022/11/07

(氨液,氨气)氨用截止阀手轮顺时针方向转时,阀杆向下移动,阀瓣下降使密封面密合,将通路切断。逆转时则开启,阀杆提到最高点上密封起作用 RETZ (Ammonia liquid, ammonia gas) When the hand wheel of the stop valve for ammonia is turned clockwise, the valve rod moves downward, the valve clack drops to make the sealing surface close, and the passage is cut off. When the valve is reversed, it will be opened, and the valve rod will be lifted to the highest point for sealing

(Ammonia liquid, ammonia gas) When the hand wheel of the stop valve for ammonia is turned clockwise, the valve rod moves downward, the valve clack drops to make the sealing surface close, and the passage is cut off. When the valve is reversed, it will be opened, and the valve rod will be lifted to the highest point for sealing

增加了一个上密封.在阀门开启状态时,与填料一起两层密封作用,并对填料有一定的保护作用 ,并可带压更换复合软成形填料 RETZ An upper seal is added to the special stop valve for liquefied gas and fuel gas When the valve is open, it has a two-layer sealing effect with the packing, and has a certain protective effect on the packing, and can replace the composite soft forming packing under pressure

进口氨用截止阀,氨气,氟利昂专用截至阀技术要求Applicable Standards

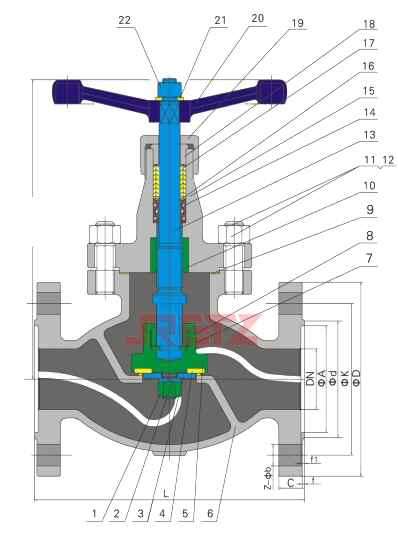

1.设计标准 Design Rating∶KS B20811,JIS B2071,GB/T12235-89;

2.结构长度Face to Face∶KS B2361,JIS B2002、GB12221-89;

3.法兰标准Flanged Ends∶JIS B2212、B2214、HG/T-20592-2009;

4.检查和试验 Inspection & Testing∶KS B2361,JIS B2003.

公称压力PN | 强度试验压力Mpa | 空气密封试验压力Mpa | 低压密封试验(Mpa) | 适用介质 |

1.6/2.5 | 3.75 | 2.75 | 0.3 | 氨液,氨水,氨气,氟利昂,冷冻液等非腐蚀性介质。 |

4 | 6 | 4.4 | 0.3 | |

10K/150LB | 3 | 2.2 | 0.3 | |

20K/300LB | 7.5 | 5.5 | 0.3 | |

使用温度℃ | WCB:(-20~+80)、LCB:(-46~+80)、F304:(-45~+80) | |||

规格尺寸 | 1/2~12" | |||

进口氨用截止阀,氨气,氟利昂专用截至阀特点说明

1.开关轻松,密封性能好 Easy switching and good sealing performance

2.阀杆填料自动密封:填料采用(PTFE+丁晴橡胶)复合软成形填料,下增加弹簧自动补偿,利用管道压力产生自动密封, 密封填料磨损弹簧自动补偿 Automatic sealing of valve stem packing: (PTFE+Buna-N rubber) composite soft shaped packing is used as the packing, and the lower spring is added for automatic compensation. The pipe pressure is used to generate automatic sealing, and the worn spring of the sealing packing is automatically compensated

3.密封填料损坏—带压更换填料。(手轮逆时针方向转到顶点,上密封产生密封,拿下手轮,松开填料室,拿下填料室,更换复合软成形填料(PTFE+丁晴橡胶+弹簧)retz品牌 The sealing packing is damaged - replace the packing under pressure. (Turn the hand wheel counterclockwise to the top, and the upper seal will produce a seal. Take off the hand wheel, loosen the packing chamber, take down the packing chamber, and replace the composite soft shaped packing (PTFE+NBR+spring)

4.阀杆耐磨功能:填料室增加 PTFE,使阀杆不会和填料室摩擦,增强阀杆使用寿命 Wear resistance function of valve rod: PTFE is added to the packing chamber to prevent the valve rod from rubbing with the packing chamber and enhance the service life of the valve rod

5.开启时将阀杆提到最高点,令填料与上密封同时起密封作用. 关闭时关闭力不要过大,以免破坏密封面 When opening, lift the valve rod to the highest point, so that the packing and upper seal play a sealing role at the same time The closing force shall not be too large to avoid damaging the sealing surface

6.密封材料特点说明

聚四氟乙烯 PTFE

耐温(-196~120℃),耐腐∶耐强酸强碱、水和各种有机溶剂。无毒害/不粘附/高润滑/耐气候机械性质较软,有“塑料王”之称 Characteristics of sealing materials: temperature resistance (- 196~120 ℃), corrosion resistance: resistance to strong acids and alkalis, water and various organic solvents. No poison/no adhesion/high lubrication/weather resistance Mechanical property is soft, so it is called "the king of plastics"

巴氏合金 Babbitt

特点∶因其呈白色,又称白合金,低硬度轴转动的材料。熔点∶固相点温度为240℃,液相点温度为370℃,极限使用温度不得超过100℃,摩擦系数在有油时为0.005,无油时为0.28 Features: because it is white, also known as white alloy, it is a material with low hardness shaft rotation. Melting point: the solid phase point temperature is 240 ℃, the liquid phase point temperature is 370 ℃, the limiting service temperature shall not exceed 100 ℃, and the friction coefficient is 0.005 with oil and 0.28 without oil.

主要零部件材料 Main parts and materials

序号 | 零件名称 | 材料 | ||

WCB | LCB | F304 | ||

1 | 六角螺母 | A194-8 | ||

2 | 弹性垫片 | F304 | ||

3 | 特大垫片 | 25# | F304 | |

4 | 密封圈 | PTFE或巴氏合金 | ||

5 | 阀瓣 | 25# | LF2 | F304 |

6 | 阀体 | WCB | LCB | CF8 |

7 | 对开环 | 25# | F304 | F304 |

8 | 阀瓣盖 | 25# | 25# | F304 |

9 | 垫片 | PTFE | ||

10 | 阀杆螺母 | 25# | LF2 | F304 |

11 | 六角螺母 | A194-2H | A194-8 | |

12 | 双头螺柱 | A193-B7 | A193-B8 | |

13 | 阀杆 | 20Cr13 | F304 | |

14 | 弹簧 | F304 | ||

15 | 阀盖 | 25# | F304 | |

16 | 填料垫圈 | F304 | ||

17 | 复合填料 | F4+丁晴橡胶 | ||

18 | 填料压盖 | 20Cr13 | F304 | |

19 | 填料压紧螺母 | 25# | F304 | |

20 | 手轮 | 成型钢板 | ||

21 | 平垫 | A3 | F304 | |

22 | 六角螺母 | A194-2H | A194-8 | |

可能发生的故障及其解决方案 Possible faults and solutions

故障现象 | 图象 | 原因 | 消除方法 |

阀盖连接处泄漏 |  | 1、螺栓未拧紧或松紧不均匀; 2、法兰密封有损伤或夹有污物; 3、垫片失效 | 1、均匀拧紧螺栓; 2、修整密封面或清除污物; 3、更换垫片。 |

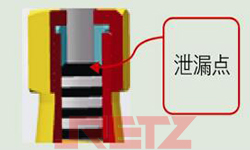

填料处泄漏 |  | 1、填料未压紧; 2、填料失效。 | 1、将填料压盖均匀压紧; 2、更换复合软成形填料检修。 |

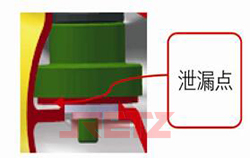

密封面泄漏 |  | 1、密封面间夹有污物; 2、密封面有损伤。 | 1、清除干净; 2、修整填料体密封面或更换PTFE密封垫。 |

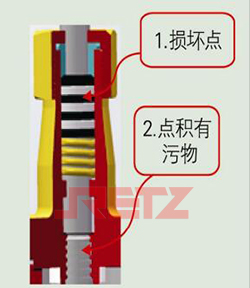

阀杆转动不灵活 |  | 1、丁晴橡胶+弹簧损坏 2、阀杆与阀杆螺母的螺纹有损伤或积有污物。 | 1、更换丁晴橡胶+弹簧/PTFE填料。2、拆开修整或清除污物。 |

在线客服

在线客服