(CTW)三位式气动执行器

简要描述:RETZ进口CTW三位式执行器主要用于三通阀或四通阀以及其他三位式旋转装置的气动控制。RETZ可以提供两种行程的三位式气动执行器,一种是90度三位式执行器

品牌:RETZ

品牌:RETZ 工况条件:气开/气关

工况条件:气开/气关 温度/压力:P-T:8bar-60℃

温度/压力:P-T:8bar-60℃ 更新时间:2022/07/12

更新时间:2022/07/12

(CTW)进口三位式气动执行器 工作原理 Working principle of three position pneumatic actuator

180°弹簧复位气动执行器在两端设计有弹簧组件,适用于0°-90°-180° 之间往复运动操作,在失去气源压力(或故障)时通过弹簧回位至90° 位置。 在全开位置180°和全关位置0°以标准方式在外部可以 精确调整±4° The 180 ° spring return pneumatic actuator is designed with spring components at both ends, which is suitable for reciprocating operation between 0 ° -90 ° -180 °, and returns to the 90 ° position through the spring in case of loss of air supply pressure (or failure). It can be accurately adjusted ± 4 ° externally in a standard way at 180 ° in the fully open position and 0 ° in the fully closed position.

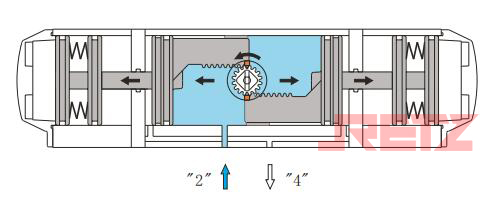

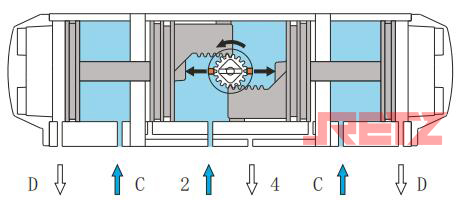

1、从90°-180° 当气源压力从气口(2)进入气缸两活塞 中间腔时,使两活塞分离向气缸两端方向 移动,迫使两端的弹簧组压缩,两端气腔 的空气通过气口(4)排出,同时使两活塞 齿条同步带动输出轴(齿轮)逆时针方向 旋转到达180° From 90 ° -180 °, when the air source pressure enters the middle chamber of the two pistons of the cylinder from the air port (2), the two pistons will separate and move towards the two ends of the cylinder, forcing the spring groups at both ends to compress, and the air in the air chambers at both ends will be discharged through the air port (4). At the same time, the two piston racks will synchronously drive the output shaft (gear) to rotate counterclockwise to 180 °

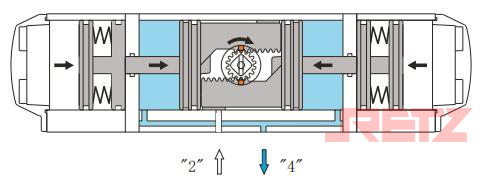

2、从90°-0° 当气源压力从气口(4)进入气缸两端气腔 时,使两活塞向气缸中间方向移动,迫使 两端的弹簧组压缩,中间气腔的空气通过 气口(2)排出,同时使两活塞齿条同步带 动输出轴(齿轮)顺时针方向旋转到达0° From 90 ° -0 °, when the air supply pressure enters the air chambers at both ends of the cylinder from the air port (4), the two pistons move towards the middle of the cylinder, forcing the spring groups at both ends to compress, and the air in the middle air chamber is discharged through the air port (2). At the same time, the two piston racks synchronously drive the output shaft (gear) to rotate clockwise to 0 °

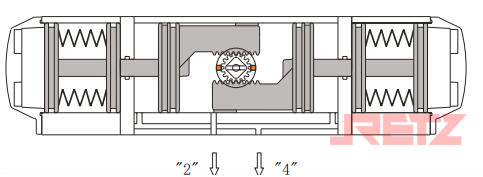

3、从失去气源压力的操作 Operation from loss of supply pressure

当位置在180°:在气口(2)失去空气压力 或电磁阀断电时,弹簧推力迫使活塞向气缸 中间方向移动,产生顺时针方向旋转至90° 位置 When the position is 180 °: when the air pressure is lost at the air port (2) or the solenoid valve is powered off, the spring thrust forces the piston to move towards the middle of the cylinder, resulting in clockwise rotation to the 90 ° position

当位置在0°:在气口(4)失去空气压力或 电磁阀断电时,弹簧推力迫使活塞向气缸 两端方向移动,产生逆时针方向旋转至90° 位置 When the position is 0 °: when the air pressure is lost at the air port (4) or the solenoid valve is powered off, the spring thrust forces the piston to move towards both ends of the cylinder, resulting in counterclockwise rotation to the 90 ° position

产品结构特点 Product structure characteristics

1、对称设计,结构紧凑。在5.5Bar压力下输出扭矩可在20到1500牛米间选型,90度三位式执行器有单用和双作用二种工作形式可选;180度三位式执行器有双作用二种工作形式可选;三段式工作行程,限位调节灵活方便。Symmetrical design, compact structure. The output torque can be selected from 20 to 1500 Nm under the pressure of 5.5Bar. The 90-degree three-position actuator has two working forms, single-acting and double-acting; the 180-degree three-position actuator has two double-acting types. Work form optional;Three-stage working stroke, flexible and convenient limit adjustment

(1)90度三位式执行器工作行程为0°~ 中位 ~90°,中间位置在20°~ 80°可调,行程末端可调,调节位置和范围分别为0±5°和 90±5° The working stroke of the 90 degree three position actuator is 0 ° ~ middle ~ 90 °, the middle position is adjustable at 20 ° ~ 80 °, the end of the stroke is adjustable, and the adjustment position and range are 0 ± 5 ° and 90 ± 5 ° respectively

(2)180度三位式执行器工作行程为0°~ 中位 ~180°,中间位置在90°~170°可调,行程末端可调,调节位置和范围分别为0±5°和 180±5° The working stroke of the 180 degree three position actuator is 0 ° ~ middle ~180 °, the middle position is adjustable at 90 ° ~170 °, and the end of the stroke is adjustable. The adjustment position and range are 0 ± 5 ° and 180 ± 5 ° respectively

2、配有外置调节螺杆,可轻松实施中间位置的手动调节和锁定 Equipped with an external adjusting screw, it can easily implement the manual adjustment and locking of the middle position

3、连接尺寸均按ISO5211和NAMUR标准设计生产,可确保阀门及附件的直接安装连接 The connection dimensions are designed and produced according to ISO5211 and NAMUR standards, which can ensure the direct installation and connection of valves and accessories

4、三段式缸体加工均采用全流程数控加工中心,一道工艺完成工件的所有加工,缸体尺寸特别是扭矩输出端的形位尺寸达到最佳精度,确保了执行器输出扭矩的最佳传递 The three-stage cylinder block is processed by the full process CNC machining center, and all the processing of the workpiece is completed by one process. The cylinder block size, especially the shape and position size of the torque output end, achieves the best accuracy, ensuring the best transmission of the actuator output torque

5、扭矩输出形式灵活多样,八角孔为标配形式,也可据IS05211标准选配双D孔和键槽孔等形式,最大限度地满足多样化阀杆的要求 Torque output forms are flexible and diverse. Octagonal hole is the standard form, and double D hole and key slot hole can also be selected according to is05211 standard, so as to meet the requirements of diversified valve stems to the greatest extent.

(CTW)进口三位式气动执行器 开关位置原理 Switch position principle

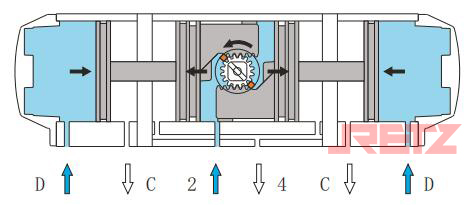

三位置气动执行器有两种型号0°-45°-90°和0°-90°-180°,在气口进气后 活塞向两端运动被两端设计有辅助活塞产生机械限制来实现中间位置; 可直接利用外面两端调节螺栓很容易调节中间位置角度, 如20°、30°、50°、75°和95°、120°、130°、 150°、175°等。There are two types of three position pneumatic actuators: 0 ° -45 ° -90 ° and 0 ° -90 ° -180 °. After the air inlet, the piston moves to both ends, which is mechanically limited by auxiliary pistons designed at both ends to achieve the middle position; The adjusting bolts at both ends of the outside can be directly used to easily adjust the angle of the middle position, such as 20 °, 30 °, 50 °, 75 ° and 95 °, 120 °, 130 °, 150 °, 175 °, etc

三位置气动执行器的操作需要设计一套电磁阀控制回路系统来完成操作,其控制原理如下:The operation of the three position pneumatic actuator requires the design of a solenoid valve control loop system to complete the operation. Its control principle is as follows:

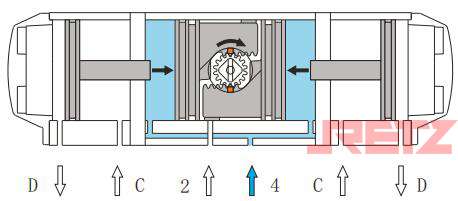

位置1(中间位置):Position 1 (middle position)

气源压力同时进入2口和D口,空气从4口 和C口排出,2口作为内部活塞移动,D是 通过辅助活塞推杆限制内部活塞定位在 预定的中间位置。The air supply pressure enters port 2 and port d at the same time, and the air is discharged from port 4 and port C. port 2 moves as an internal piston, and port D restricts the internal piston to be positioned in the predetermined middle position through the auxiliary piston push rod.

位置2(全开位置)Position 2 (full open position)

气源压力同时进入2口和C口,空气从4口 和C口排出,2口的内部活塞继续移动,C口 为解除辅助活塞推杆限制定位,使内部 活塞顺利到达全开位置。The air supply pressure enters port 2 and port C at the same time, and the air is discharged from port 4 and port C. the internal piston of port 2 continues to move. Port C is positioned to release the limit of the auxiliary piston push rod, so that the internal piston can reach the full open position smoothly.

位置3(全关位置)Position 3 (fully closed position)

气源压力进4口,空气从2口排出,内部活塞 向中间方向移动到达全关位置。 可提供0°-45°-90°弹簧回位型号规格, 在断气断电时(或气源故障),通过弹簧 迫使内部活塞回位到全关位置。The air supply pressure enters 4 ports, the air is discharged from 2 ports, and the internal piston moves to the middle direction to reach the fully closed position. Models and specifications of 0 ° -45 ° -90 ° spring return can be provided. In case of air and power failure (or air supply failure), the internal piston is forced to return to the fully closed position by the spring.

在线客服

在线客服