RETZ进口品质 APT14自动疏水阀泵

简要描述:RETZ (APT14)进口自动疏水阀泵具有提高效率和延长寿命的双重功能,能确保良好地控制蒸汽设备,设计成一个封闭系统,没有任何的蒸汽泄漏,也没有闪蒸蒸汽的能量浪费,即便是动力蒸汽的废气也能返回至用汽系统

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨 工况条件:疏水

工况条件:疏水 温度/压力:P-T: 16bar@220℃

温度/压力:P-T: 16bar@220℃ 更新时间:2023/01/05

更新时间:2023/01/05

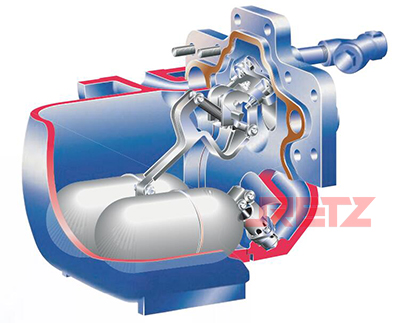

功能原理 Functional principle

(APT14)进口自动疏水阀泵是一整套完整的过程和换热设备冷凝水排放的产品,选型简单、安装方便。这种结构紧凑、全自动操作的疏水阀泵能确保过程设备在所有的工况下,甚至是真空下,均能有效排放冷凝水,从而使换热器的热效率最大 retz品牌(APT14) Imported automatic drain valve pump is a complete set of products for condensate discharge of process and heat exchange equipment, with simple selection and convenient installation. This compact, fully automatic trap pump can ensure that the process equipment can effectively discharge condensate under all working conditions, even under vacuum, so as to maximize the heat efficiency of the heat exchanger

技术范围 Technical scope

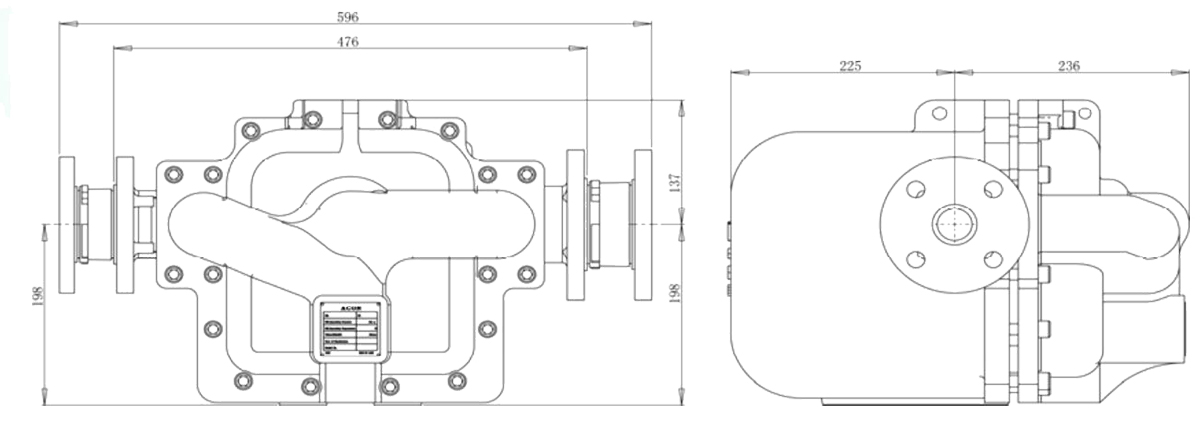

泵体设计压力:PN16 Design pressure of pump body: PN16

进/出口接口:法兰,进口 DN50,出口 DN40 Inlet/outlet interface: flange, inlet DN50, outlet DN40

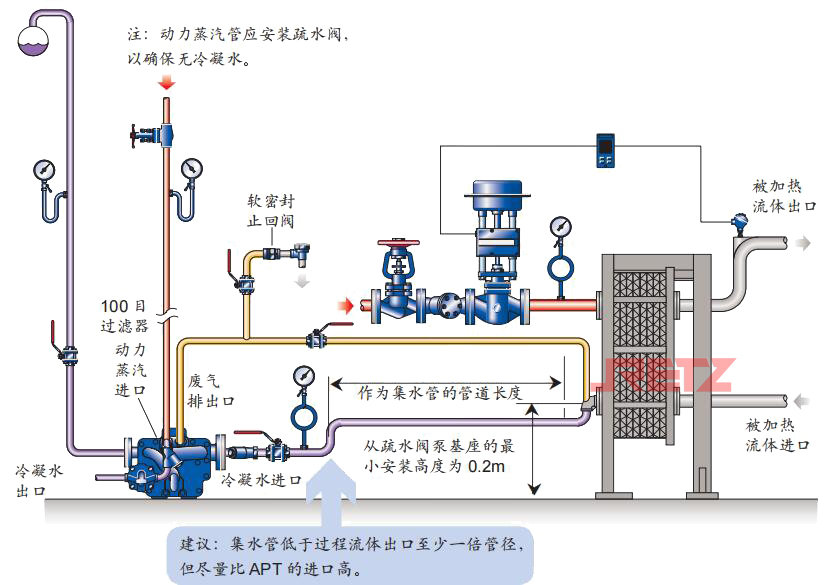

内置的不锈钢泵机构:从泵基座的最小安装高度为 0.2m Built in stainless steel pump mechanism: the minimum installation height from the pump base is 0.2m

内置的不锈钢疏水结构:浮球操作的高排量疏水阀机构 Built in stainless steel drain structure: float operated high displacement drain valve mechanism

最大操作压力:13.8 barg ,最大背压:5 barg Maximum operating pressure: 13.8 barg, maximum back pressure: 5 barg

最大操作温度:198℃ Maximum operating temperature: 198 ℃

泵排量:Max 3000 kg/h—12 Barg

疏水排量:Max 6000 kg/h—12 Barg

主要零件材质 Material of main parts

泵体:球墨铸铁 Pump body: nodular cast iron

阀芯:硬质不锈钢 Valve element: hard stainless steel

阀座:硬质不锈钢 Valve seat: hard stainless steel

浮球:不锈钢 Float ball: stainless steel

弹簧:Inconelx-750 合金 Spring: Inconelx-750 alloy

外形尺寸图 Outline dimension drawing

特征

• 结构紧凑,泵体采用球墨铸铁一次铸造成型,韧性好,耐腐蚀 Compact structure, the pump body is made of ductile iron by one-time casting, with good toughness and corrosion resistance

• 从自动疏水阀泵的基座只需 0.2m 的安装高度就能操作 Only 0.2m installation height is required to operate from the base of automatic drain valve pump

• 容易安装至低位置的过程设备 Process equipment easy to install in low position

• 在所有的情况下都能排放冷凝水,甚至是真空工况

• 无需电力,无任何旋转部件,不会产生汽蚀损坏 ,几乎不消耗能源 - 适用于危险区域 No power, no rotating parts, no cavitation damage, almost no energy consumption - suitable for hazardous areas

• 排量高

• 弹簧组件采用耐高温合金不锈钢 X-750,耐高温, 耐疲劳 The spring assembly is made of heat-resistant alloy stainless steel X-750, which is heat-resistant and fatigue resistant

• 高强度整体执行机构组件设计,不易变形,可承受 更高的动力蒸汽压力和温度 High strength integral actuator component design, not easy to deform, can withstand higher power steam pressure and temperature

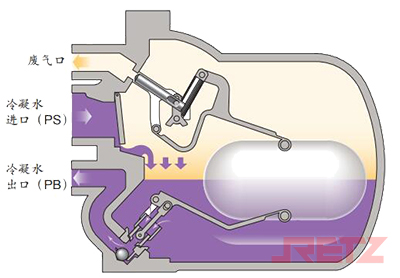

工作循环 Duty cycle

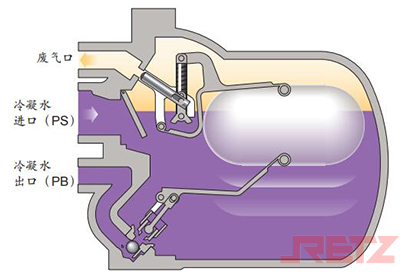

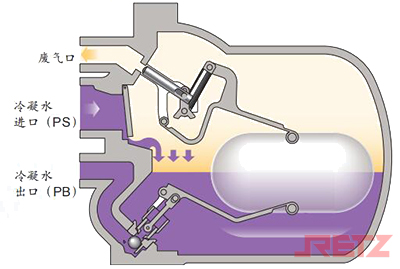

1.自动疏水阀泵是根据正压排放原理工作。冷凝水通过进口挡板式止回阀进入泵体内,浮球升起。浮球通过多连接轴销连接至疏水阀机构 The automatic drain valve pump works according to the principle of positive pressure discharge. Condensate enters the pump body through the inlet baffle check valve, and the float rises. The float ball is connected to the drain valve mechanism through multiple connecting pins

body through the inlet baffle check valve, and the float rises. The float ball is connected to the drain valve mechanism through multiple connecting pins

如果上游蒸汽压力 PS 足够高能克服背压 PB(见下图),则两级疏水阀机构将工作并排出冷凝水。浮球根据进入 APT14 内的冷凝水量自动调节,控制疏水阀的开度 If the upstream steam pressure PS is high enough to overcome the back pressure PB (see the figure below), the two-stage trap mechanism will work and discharge condensate. Float ball is automatically adjusted according to the amount of condensed water entering APT14 to control the opening of drain valve.

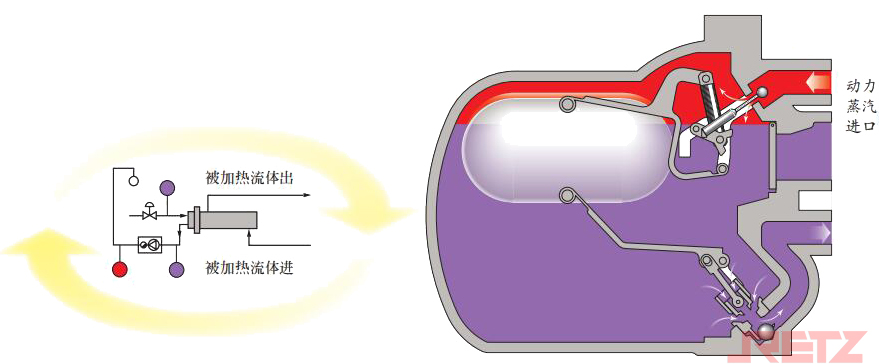

2.对一些温度控制设备,有可能出现系统的蒸汽压力 PS 低于背压 PB 的情况。此时标准的疏水阀将无法工作,冷凝水将会积聚在设备内 For some temperature control equipment, the steam pressure PS of the system may be lower than the back pressure PB. At this time, the standard steam trap will not work, and condensate will accumulate in the equipment

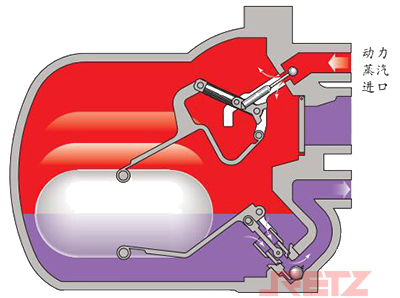

3.但是,对于 APT,冷凝水只是注满泵体 - 使浮球继续升起,直至触发转换连杆打开动力蒸汽进口阀,同时关闭废气排放阀 However, for APT, the condensate is only used to fill the pump body - so that the float continues to rise until the changeover linkage is triggered to open the power steam inlet valve and close the exhaust valve

4.快速动作的机构确保从疏水阀模式至动力泵排放模式的快速转换。动力蒸汽阀打开,APT 内部的压力将超过背压,冷凝水会通过疏水阀的阀座排出至冷凝水系统 The quick action mechanism ensures the quick conversion from the drain valve mode to the power pump discharge mode. When the power steam valve is opened, the pressure inside APT will exceed the back pressure, and the condensate will be discharged to the condensate system through the valve seat of the steam trap

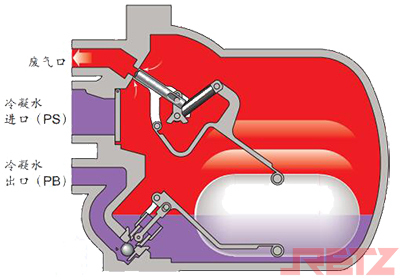

5.当冷凝水位下降时,浮球使转换连杆重新动作,使动力蒸汽进口阀关闭,废气排放阀打开 When the condensate water level drops, the float ball will make the changeover connecting rod act again, so that the power steam inlet valve is closed and the exhaust valve is opened

6.通过废气阀,当 APT 内部的压力和冷凝水进口的压力相等时,冷凝水再次通过进口挡板式止回阀进入阀体内。同时,出口球形止回阀确 保没有冷凝水回入阀体内,这样疏水循环或泵工作循环再次开始 Through the exhaust valve, when the pressure inside APT is equal to the pressure at the condensate inlet, the condensate enters the valve body again through the inlet flapper check valve. At the same time, the outlet ball check valve ensures that no condensate returns to the valve body, so that the drainage cycle or pump working cycle starts again

保没有冷凝水回入阀体内,这样疏水循环或泵工作循环再次开始 Through the exhaust valve, when the pressure inside APT is equal to the pressure at the condensate inlet, the condensate enters the valve body again through the inlet flapper check valve. At the same time, the outlet ball check valve ensures that no condensate returns to the valve body, so that the drainage cycle or pump working cycle starts again

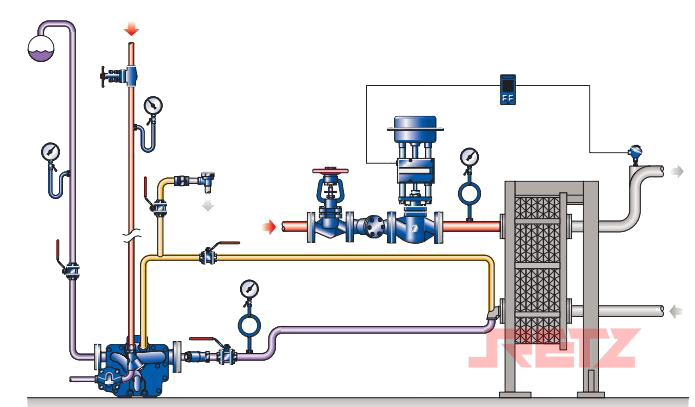

典型应用 Typical Applications

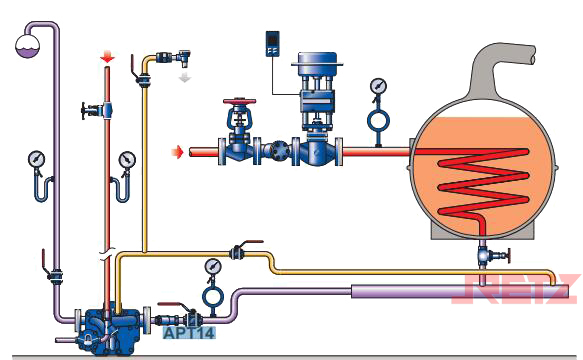

从工艺过程容器和换热器中排放冷凝水---

Drain condensate from process vessels and heat exchangers

在空间受限制的情况下设计成闭环或密封系统。在所有的压力工况下有效地排除冷凝水,确保换热器的正常工作。可以避免管道的腐蚀、噪音、水锤等问题,从而延长设备的APT14 使用寿命 It is designed as a closed loop or sealing system when space is limited. Condensate shall be effectively drained under all pressure conditions to ensure the normal operation of heat exchanger. It can avoid corrosion, noise, water hammer and other problems of the pipeline, thus prolonging the service life of the equipment APT14

从管壳式换热器中排放冷凝水(封闭系统)—

Drain condensate from shell and tube heat exchanger (closed system)

APT 能方便地和管壳式换热器的出口连接 APT can be conveniently connected to the outlet of shell and tube heat exchanger

无需破真空器就能够 No vacuum breaker is required

• 在所有的工况下均能有效排放冷凝水 Condensate can be effectively discharged under all working conditions

• 能保证换热器温度控制准确性 It can ensure the accuracy of heat exchanger temperature control

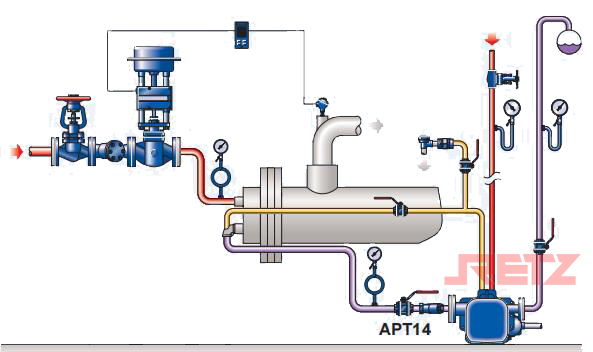

从真空设备中排放冷凝水(封闭系统)—

Drain condensate from vacuum equipment (closed system)

对该难题提供了简单、有效的解决方法。APT 的操作无需很高的正吸水头,从其底部基座只需 0.2m的APT14 的安装距离就能从真空系统中排除冷凝水 It provides a simple and effective solution to this problem. The operation of APT does not require a very high positive suction head, and condensate can be removed from the vacuum system only by an installation distance of 0.2m APT14 from its bottom base.

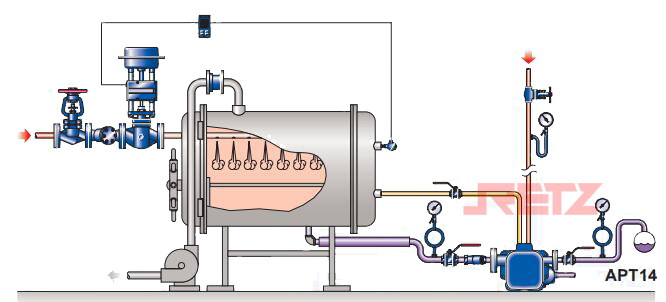

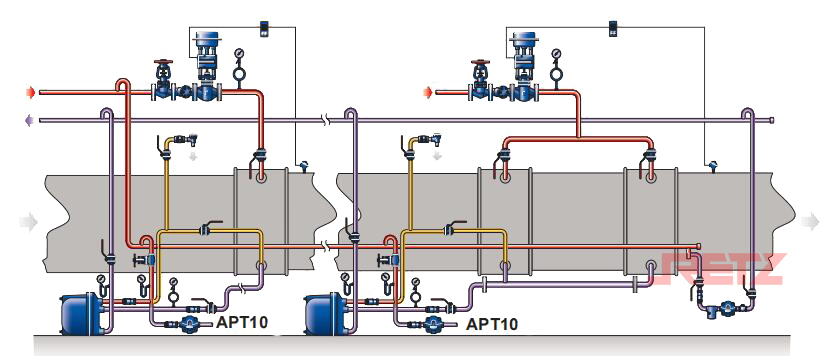

从多个换热器中排放冷凝水(封闭系统)—

Drain condensate from multiple heat exchangers (closed system)

APT 可用于单个或由一个控制阀控制的多个换热器 - 只要总负载在 APT 的排量范围内。由于冷凝水的积聚,空气换热组特别容易受到腐蚀和冰冻的影响 APT can be used for single or multiple heat exchangers controlled by a single control valve - as long as the total load is within APT's displacement range. The air heat exchanger unit is particularly vulnerable to corrosion and freezing due to the accumulation of condensate

APT 为传统的空气加热器提供了一个完整的解决方法,APT 是安装位置受限制的最理想的选择 APT provides a complete solution for the traditional air heater, and APT is the best choice when the installation location is limited

推荐的安装 Recommended Installation

在线客服

在线客服