RETZ进口品质 小型十字轴万向联轴器(双节,单节)

简要描述:RETZ进口小型十字轴万向联轴器(双节,单节)通常用于包装机械,木工机械,多头钻,冶金机械各种特殊传动场合

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨  工况条件:联结机械

工况条件:联结机械 温度/压力:11.2-1120N.m

温度/压力:11.2-1120N.m 更新时间:2023/02/25

更新时间:2023/02/25

产品用途 Product use

1.进口小型十字轴万向联轴器(双节,单节)适用于各种通用机械场合,销钉方块结构最高使用1000转/分,滚针轴承结构最高转速可达4000转/分,建议实际使用转速在最高转速的50%以内使用 retz The imported small cross shaft universal joint (double joint, single joint) is applicable to various general  mechanical occasions. The maximum speed of pin block structure can be 1000 rpm, and the maximum speed of needle bearing structure can be 4000 rpm. It is recommended that the actual speed should be within 50% of the maximum speed

mechanical occasions. The maximum speed of pin block structure can be 1000 rpm, and the maximum speed of needle bearing structure can be 4000 rpm. It is recommended that the actual speed should be within 50% of the maximum speed

2.适用于联结空间同一平面上两轴夹角每节极限转动角度为45度,允许使用角度30度以内 Applicable to the included angle of two shafts on the same plane of the connecting space. The limit rotation angle of each section is 45 degrees, and the allowable angle is within 30 degrees

3.所提供的快速锁紧装置仅有公差为H7的成品孔,带标准的键槽或六角孔可选,可非标定制不同安装结构 The provided quick locking device only has finished hole with tolerance of H7, with standard keyway or hexagonal hole optional, and different installation structures can be customized non-standard

4.适用于联结空间同一平面上两轴轴线夹角≤30°的传动 Applicable to the transmission with the included angle of two axes on the same plane of the connecting space ≤ 30 °

5.传递公称转矩11.2-1120N.m.(可定制更大扭矩)Transmit nominal torque 11.2-1120 N.m. (larger torque can be customized)

6.常规键槽顶丝孔,可按照要求定制不同孔型和固定方式 Conventional keyway jackscrew hole can be customized with different hole types and fixing methods according to requirements

7.允许两轴间夹角在限定的范围内随工作需要而变动 The included angle between the two shafts is allowed to change with the work needs within the limited range

结构特点 Structural features

产品材质: 常规40Cr高碳钢,可定制304 316 等特殊材质 Product material: conventional 40Cr high carbon steel, customized 304 316 and other special materials

1.适用于联结空间同一平面上两轴轴线夹角β≤45°的传动场合,传递公称转矩11.2-1120N.m Applicable to the included angle of two axes on the same plane of connecting space β≤ 45 ° transmission, transmission nominal torque 11.2-1120N. m

2.每节最大轴间夹角45 Maximum angle between shafts of each section 45

3.成品孔公差H7,可根据要求开键槽,六角孔和四方孔 Finished hole tolerance H7, keyway, hexagonal hole and square hole can be opened as required

4.允许两轴间夹角在限定的范围内随工作需要而变动 The included angle between the two shafts is allowed to change with the work needs within the limited range

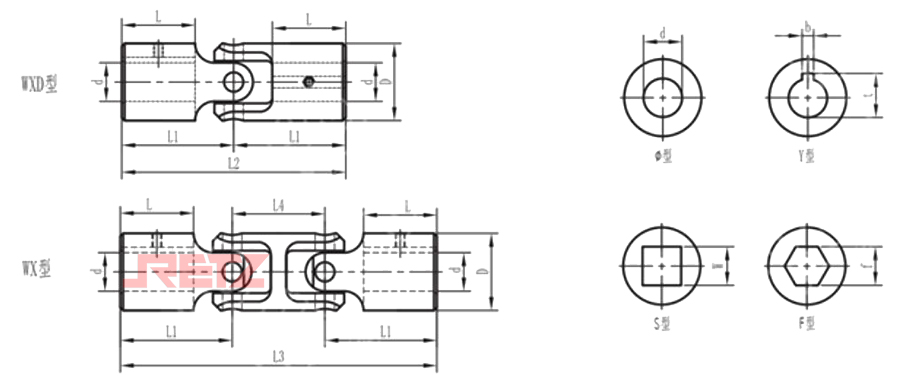

型号 | 公称扭矩N.m | dmax | D | L | L1 | L2 | L3 | L4 | 转动惯量Kg.m² | |

WXD单节 | WX双节 | |||||||||

WX1 | 11.2 | 10 | 16 | 22 | 30 | 60 | 80 | 20 | 0.05 | 0.07 |

WXD1 | ||||||||||

WX2 | 22.4 | 12 | 20 | 22 | 32 | 64 | 90 | 26 | 0.09 | 0.15 |

WXD2 | ||||||||||

WX3 | 45 | 14 | 25 | 27 | 40 | 80 | 112 | 32 | 0.15 | 0.22 |

WXD3 | ||||||||||

WX4 | 71 | 18 | 32 | 30 | 46 | 92 | 130 | 38 | 0.32 | 0.49 |

WXD4 | ||||||||||

WX5 | 140 | 22 | 40 | 38 | 58 | 116 | 164 | 48 | 0.59 | 0.91 |

WXD5 | ||||||||||

WX6 | 280 | 28 | 50 | 44 | 69 | 138 | 196 | 58 | 1.03 | 1.64 |

WXD6 | ||||||||||

WX7 | 560 | 35 | 60 | 60 | 91 | 182 | 252 | 70 | 2.31 | 3.38 |

WXD7 | ||||||||||

WX8 | 1120 | 42 | 75 | 84 | 122 | 244 | 336 | 92 | 4.41 | 6.63 |

WXD8 | ||||||||||

注:1、表中联轴器重量,转动惯量是近似值。2、当轴线夹角落β+O时,联轴器的许用转矩【T】=Tncos8.3、中间轴尺寸L4可根据需要确定。

Note: 1. The weight and moment of inertia of the coupling in the table are approximate values. 2. When the axis clamps the corner β+ When O, the allowable torque of the coupling [T]=Tncos8.3, and the size of the intermediate shaft L4 can be determined as required.

安装及选用 Installation and selection

要保证旋转运动的等角速和主、从动轴之间保持同步转动,应选用双十字轴万向联轴器或两个单十字轴万向联轴器组合在一起,并满足以下三个条件:a中间轴与主、从动轴间的夹角相等,b中间轴两端叉头的对称面在同一平面内x中间轴与从动轴线在同一平面内,安装单十字轴万向联轴器时,主、从动端角度不等,主、从动轴之间不能保持同步转动;其不同步性随着夹角变而变。

To ensure the constant angular speed of rotation and the synchronous rotation between the main and driven shafts, double spider universal couplings or two single spider universal couplings should be selected and combined, and the following three conditions should be met: a The included angle between the intermediate shaft and the main and driven shafts is equal, b The symmetry plane of the fork heads at both ends of the intermediate shaft is in the same plane x The intermediate shaft and the driven shaft are in the same plane. When installing the single spider universal coupling The angle of the driven end is different, and the driving and driven shafts cannot keep synchronous rotation; Its asynchrony changes with the included angle.

在线客服

在线客服