RETZ进口品质 RVP变量叶片泵

简要描述:RETZ (RVP)进口变量叶片泵采用特殊的限压式变量机构,可实现低压大流量,高压小流量,使功率最合理的运用,有效降低电机消耗功率,节约能源。 适用于金属切削机床、压力机械以及其它有变量或保压要求的液压系统

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨 工况条件:变量柱塞泵

工况条件:变量柱塞泵 温度/压力:变量叶片泵

温度/压力:变量叶片泵 更新时间:2022/08/01

更新时间:2022/08/01

(RVP)进口变量叶片泵 性能 performance

1.具有压力调整和流量调节装置,压力和流量都可以调整 With pressure adjustment and flow adjustment devices, both pressure and flow can be adjusted

2.当系统压力高于泵调定压力时流量减少,使功率损失降为最低,效率高,安全可靠 When the system pressure is higher than the set pressure of the pump, the flow is reduced, so that the power loss is minimized, with high efficiency, safety and reliability

3.侧板采用液压平衡,可获得更好的容积效率 The side plate is hydraulically balanced to obtain better volumetric efficiency

4.采用数种隔音、防震的措施、低噪声、无震动 Several sound insulation and shock proof measures are adopted, with low noise and no vibration

5.内置压力调整阀,系统无需加装调压阀 retz品牌 Built in pressure regulating valve, the system does not need to install pressure regulating valve

6.可连接直接式电机,安装简便 It can be connected to a direct motor, which is easy to install

(RVP)进口变量叶片泵 型号说明 Model description

VP | 20 | A2 | R |

系列号 | 名义流量 | 调压范围kgf/cm² | 旋转方向 |

低压变量叶片泵 | 在1800rpm 3.5kgf/cm²时的流量 | A 18-20 B 215~35 C 330-70 | R:顺时针(从轴端看) 所有变量叶片泵转向为顺时针方向 |

RVP变量叶片泵 参数表 Parameter table

型号 | 排量(cc/rev) | 最高使用压力(kgfcm² ) | 转速范围(rpm) | 配管尺寸 | 重量(kg) | ||

进口 | 出口 | 泄油口 | |||||

VP1-12 VP1-15 VP1-20 VP2-30 VP2-40 | 6.6 8.3 11.1 16.6 22.2 | 70 | 800~1800 | 1/2" | 3/8" | 1/4" | 5 |

3/4" | 1/2” | 1/4" | 9.1 | ||||

RVP变量叶片泵使用说明:

●转动方向: 顺时针方向(从轴端看)为标准品,逆时针方向为特殊式样。回转方向的确认可由瞬时起动马达来检查 Rotation direction: clockwise (from the shaft end) is the standard, and counterclockwise is the special style. The confirmation of the rotation direction can be checked by the instantaneous starting motor

●液压油: 70bar以下,使用40℃时粘度30-50cSt(ISO VG32)的液压油 Hydraulic oil: below 70bar, use hydraulic oil with viscosity of 30-50cst (ISO vg32) at 40 ℃

●泄油管压力:泄油管一定要直接接到油箱的油面下,而配置所产生的背压请维持在0.3bar以下 Pressure of drain pipe: the drain pipe must be directly connected to the oil level of the oil tank, and the back pressure generated by the configuration should be maintained below 0.3bar

●工作油温: 连续运转的温度为15-16℃ Working oil temperature: the temperature of continuous operation is 15-16 ℃

●轴心配合: 泵轴与马达轴之轴心误差为0.05mm,角度误差为1度 Axis fit: the axis error of pump shaft and motor shaft is 0.05mm, and the angle error is 1 degree

●吸油压力: 吸油口的压力为-0.3bar至0.3bar Oil suction pressure: the pressure of the oil suction port is -0.3bar to 0.3bar

●排量调整: 调整排量时,先放松调节螺帽,再旋转调整螺丝,右转减少流量,而左转则增加,调整完毕请上紧螺丝 Displacement adjustment: when adjusting the displacement, loosen the adjusting nut first, then rotate the adjusting screw, turn right to reduce the flow, and turn left to increase it. Please tighten the screw after adjustment

●压力调整: 右转压力调整螺丝,使输出压力降低,左转则升高 Pressure adjustment: turn the pressure adjusting screw right to reduce the output pressure, and turn left to increase it

●峰值: 峰值不得超过140bar Peak value: the peak value shall not exceed 140bar

●新机运转: 新机开始运转时,可在无压力的状态下反复起动电机马达,以排除泵内和吸油管中的空气,为确保系统内的空气排除,可在无负载的状态下连续运转10分钟 New machine operation: when the new machine starts to operate, the motor can be started repeatedly without pressure to eliminate the air in the pump and the oil suction pipe. In order to ensure the elimination of air in the system, it can operate continuously without load for 10 minutes

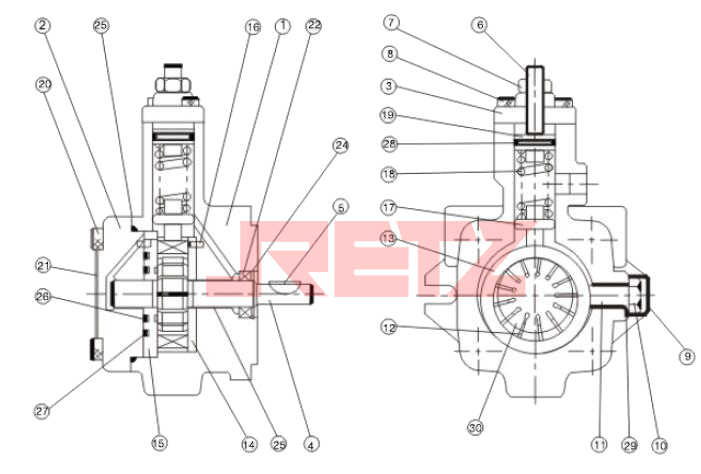

VP-12/15/20材质表

编号 | 零件名称 | 编号 | 零件名称 |

1 | 泵体 | 16 | 定位销 |

2 | 后盖 | 17 | 活塞 |

3 | 调压柱盖 | 18 | 弹簧 |

4 | 心轴 | 19 | 推杆 |

5 | 半圆键 | 20 | 六角螺栓-B |

6 | 调压螺栓 | 21 | 标牌 |

7 | 调压螺母 | 22 | 油封 |

8 | 六角螺栓-A | 23 | 自润轴承 |

9 | 防压套 | 24 | 卡簧 |

10 | 噪音调整螺帽 | 25 | O形圈-A |

11 | 噪音调整螺栓 | 26 | O形圈-B |

12 | 叶片 | 27 | O形圈-C |

13 | 定子 | 28 | O形圈-D |

14 | 前侧板 | 29 | O形圈-E |

15 | 后侧板 | 30 | 转子 |

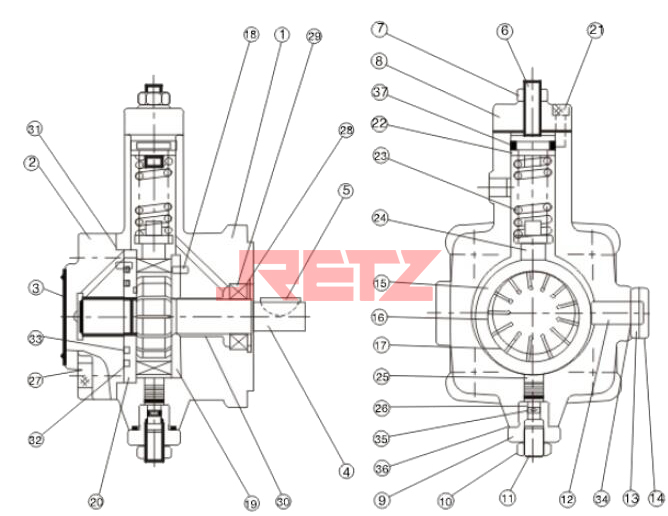

VP-30/40材质表

编号 | 零件名称 | 编号 | 零件名称 |

1 | 泵体 | 20 | 后侧板 |

2 | 后盖 | 21 | 六角螺栓-A |

3 | 标牌 | 22 | 推杆 |

4 | 主轴 | 23 | 弹簧 |

5 | 半圆键 | 24 | 大活塞 |

6 | 调压螺栓 | 25 | 小活塞 |

7 | 调压螺母 | 26 | 控制小活塞推杆 |

8 | 调压柱盖 | 27 | 六角螺栓 |

9 | 流量黑头 | 28 | 卡簧 |

10 | 锁紧螺帽母 | 29 | 油封 |

11 | 流量调整螺栓 | 30 | 自润轴承 |

12 | 噪音调整螺栓 | 31 | O形圈-A |

13 | 噪音调整螺帽 | 32 | O形圈-B |

14 | 防压套 | 33 | O形圈-C |

15 | 定子 | 34 | O形圈-D |

16 | 转子 | 35 | O形圈-E |

17 | 叶片 | 36 | O形圈-F |

18 | 定位销 | 37 | O形圈-G |

19 | 前侧板 |

在线客服

在线客服