RETZ进口品质 水减压阀 水力调节阀

简要描述:RETZ进口水减压阀(水力调节阀)控制主阀的固定出口压力,不因主阀上游进口压力变化而改变,亦不因主阀下游出口用水量变化而改变其出口压力。可用于生活给水、消防系统及工业给水系统

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨  工况条件:水力调节

工况条件:水力调节 温度/压力:P-T: 25bar@100℃

温度/压力:P-T: 25bar@100℃ 更新时间:2023/04/14

更新时间:2023/04/14

产品描述 Product Description

进口水减压阀(水力调节阀)在需要减静压和动压的场合可以取代中间水箱,阀体采用了全通道流线型设计,流体阻力小,流量大。在转动方式上采用了水力操作,即利用管路中的进出口水压差自动操作主阀瓣的上下移动,控制阀口开度,调节下游压力,使下游压力维持在导阀弹簧设定的压力值上。当下游压力超过设定值时,减压阀将自动关闭,不管入口压力怎样波动,都可输出稳定的出口压力。不管下游流量怎样变化,都能维持出口压力稳定在导阀设定值上。同时通过导阀调节的出口压力调节范围大,可达阀前压力10-80%,且工作平衡,无水锤冲出现象。

The inlet water pressure reducing valve (hydraulic control valve) can replace the middle water tank in the situation where static pressure and dynamic pressure need to be reduced. The valve body adopts the full channel streamline design, with small fluid resistance and large flow. In terms of rotation, hydraulic operation is adopted, which utilizes the water pressure difference between the inlet and outlet in the pipeline to automatically operate the up and down movement of the main valve disc, control the valve opening, adjust the downstream pressure, and maintain the downstream pressure at the pressure value set by the guide valve spring. When the downstream pressure exceeds the set value, the pressure reducing valve will automatically close, and regardless of how the inlet pressure fluctuates, it can output stable outlet pressure. No matter how the downstream flow changes, the outlet pressure can be maintained stable at the set value of the pilot valve. At the same time, the outlet pressure regulated by the pilot valve has a large adjustment range, reaching 10% -80% of the front pressure of the valve, and the work is balanced without water hammer impact.

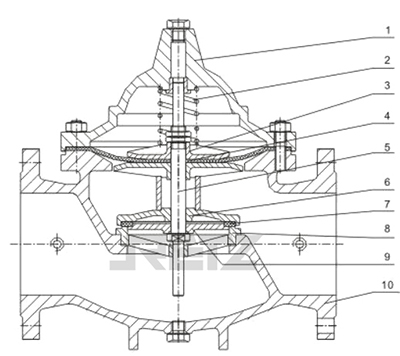

结构和主要零件材质 Structure and main component materials

结构形式为液控截止形式,按不同口径采用橡胶膜片和活塞式连接阀盖瓣开启、关闭的形式 The structure is in the form of hydraulic control cut-off, with rubber diaphragm and piston type connection valve cover disc opening and closing according to different diameters

水减压阀由主阀、导阀、针阀、球阀、微型过滤器和压力表等组成,由于导阀、针阀和压力表等要用外接导管与主阀相连接The water pressure reducing valve is composed of a main valve, a guide valve, a needle valve, a ball valve, a micro filter, and a pressure gauge. As the guide valve, needle valve, and pressure gauge need to be connected to the main valve through an external conduit

主要零件材质 Main component materials

编号No. | 零件名称Name | 主 要 材 质Material |

1 | 阀盖 | 灰铸铁、球墨铸铁、碳素钢、不锈钢 |

2 | 压缩弹簧 | 硅锰钢、铬钒钢、不锈钢 |

3 | 膜片压板 | 黄铜、碳素钢、球墨铸铁 |

4 | 膜片 | 丁晴橡胶 |

5 | 阀杆 | 不锈钢 |

6 | 阀板 | 黄铜、碳素钢、球墨铸铁 |

7 | 密封圈 | 丁晴橡胶 |

8 | 阀座 | 黄铜、不锈钢、碳素钢 |

9 | 阀板压板 | 黄铜、碳素钢、球墨铸铁 |

10 | 阀体 | 灰铸铁、球墨铸铁、碳素钢、不锈钢 |

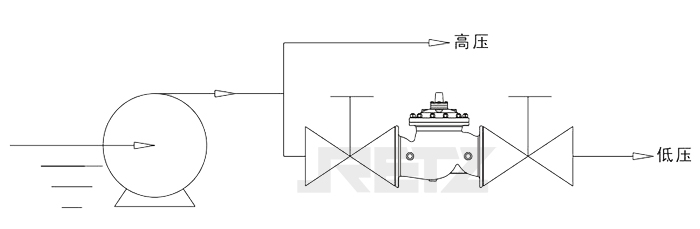

工作原理

进口水减压阀分隔膜式和活塞式两大类,RETZ提供的口径DN350以下的采用隔膜式,DN400以上的采用活塞式,两种形式的动作原理相同:进口压力P1通过导管和针阀(参看结构图)进入主阀的控制室,并建立向下的压力P3。出口压力P2也通过导管作用在导阀的膜片(或活塞)下并与导阀的调节弹簧相对抗。当下游压力超过导阀弹簧设定值时,导阀关闭,控制室内水不能排出,可变压力P3达到最大值,则主阀瓣压紧阀座,使减压阀关闭。一旦下游压力P2降到导阀弹簧设定值时,导阀开启,控制室内的压力水将通过导阀、球阀排泄到下游。由于针阀开度小,并且入口导管比出口导管直径小,所以排泄速度大于入口压力补水速度,由此控制室内的压力P3减小,一直作用在主阀瓣下面的入口压力P1将主阀瓣托起,从而打开减压阀。在移定调节状态,排泄流量等于补水流量,主阀口开度不变,下游压力稳定。

RETZ The inlet water pressure reducing valve is divided into two categories: diaphragm type and piston type. RETZ provides diaphragm type for diameters below DN350, and piston type for diameters above DN400. The action principle of both forms is the same: the inlet pressure P1 enters the control room of the main valve through a conduit and needle valve (see structural diagram), and a downward pressure P3 is established. The outlet pressure P2 also acts on the diaphragm (or piston) of the pilot valve through a conduit and opposes the regulating spring of the pilot valve. When the downstream pressure exceeds the set value of the pilot valve spring, the pilot valve closes, and the water in the control room cannot be discharged. When the variable pressure P3 reaches its maximum value, the main valve disc presses against the valve seat, causing the pressure reducing valve to close. Once the downstream pressure P2 drops to the set value of the pilot valve spring, the pilot valve opens, and the pressure water in the control room will be discharged downstream through the pilot valve and ball valve. Due to the small opening of the needle valve and the smaller diameter of the inlet duct compared to the outlet duct, the discharge velocity is greater than the inlet pressure replenishment velocity. As a result, the pressure P3 in the control room decreases. The inlet pressure P1, which has been acting below the main valve disc, lifts the main valve disc and opens the pressure reducing valve. In the adjustable state, the discharge flow is equal to the make-up water flow, the opening of the main valve remains unchanged, and the downstream pressure is stable.

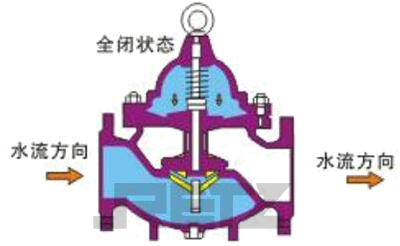

关闭状态:当主阀进口端水压分别进入阀体及控制室,且主阀的外部球阀同时关闭,此时主阀处于关闭状态。

Fully closed state: When the water pressure at the inlet end of the main valve enters the valve body and control room respectively, and the external ball valve of the main valve is closed at the same time, the main valve is in a fully closed state

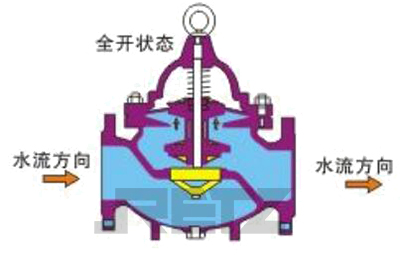

开启状态:当主阀外部的球阀全开后,此时控制室内水压全部释放到管路下游,而主阀也呈现为开启状态。

Fully open state: When the ball valve outside the main valve is fully open, all the water pressure in the control room is released to the downstream of the pipeline, and the main valve also shows a fully open state

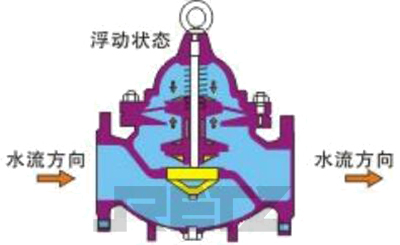

浮动调节状态:调节主阀外部的球阀开度,使进水端流向控制室的水流和控制室流向下游的水流达到平衡,此时主阀处于调节浮动状态。

Floating adjustment state: Adjust the opening of the ball valve outside the main valve to balance the water flow from the inlet end to the control room and the water flow from the control room to the downstream. At this time, the main valve is in the floating adjustment state

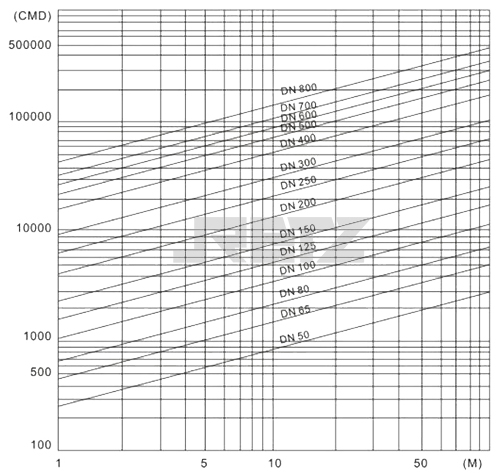

流量示意图 Flow diagram

安装与调试 Installation and debugging

安装

1、主阀最佳安装方式是水平卧式安装,阀盖朝上,其它安装方式也可达到操作功能;

2、通水前须(利用旁通管或其他措施)冲洗管路系统,清除施工杂质;

3、要求在阀前安装Y形过滤器,并定期清洗(半年至一年);

4、最好水平方向安装,阀盖朝上,如垂直安装,寿命比水平安装稍短;

5、当减压比大于4:1时,建议二级串联减压,减少气蚀,延长寿命;

6、旁通管隔离阀须关闭严密,建议选用进口蝶阀或截止阀。

2调试

导阀与导管控制系统已于出厂前装配和调整完毕,如导阀出厂设定压力值不适合现场要求可作如下调整:

1、先松开导阀的保险盖,然后将导阀的调节螺杆退拧至最上位置(相对出口最低压力)。

2、再慢慢顺时针拧动导阀的调节螺杆,出口压力将逐渐升高直到设定值为止。后装上保险盖。

3、同时要调节针阀开度,使水流经过针阀和导阀的水流达到平衡,此时下游压力达到更稳(顺时针拧动针阀手轮为减少开度,逆时针为增加开度)。

4、调整过头,须从第一步开始重调,即只能从低压往高压调。

在线客服

在线客服