RETZ进口品质 RHG内啮合齿轮泵

简要描述:RETZ(RHG)进口内啮合齿轮泵采用轴向和径向压力补偿设计,即使在低转速和低粘度下仍保持较高的容积效率。超低的噪音,采用高强度铸铁和内部独特的消音设计,使噪音更低

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨 工况条件:内啮合齿轮泵

工况条件:内啮合齿轮泵 温度/压力:P-T:160bar-60℃

温度/压力:P-T:160bar-60℃ 更新时间:2022/08/02

更新时间:2022/08/02

(RHG)进口内啮合齿轮泵 介绍

RHG0系列 规格10…20 RHG0 Series displacement 10…20

RHG1系列 规格25···63 RHG1 Series displacement 25…63

RHG2系列 规格 63…160 RHG2 Series displacement 63…160

性能 performance

采用轴向和径向压力补偿设计,即使在低转速和低粘度下仍保持较高的容积效率 retz品牌 With special design of pressure compensate,it is High Volumetriic efficiency even when low rotation speed and low viscosity.

超低的噪音,采用高强度铸铁和内部独特的消音设计,使噪音更低 The noise is very low.Adopt high-strength iron casting and specialnoise-deduction design inside,the noise of pump is much lower.

极低的流量和压力脉动,在低速状况仍可保持稳定的流量和压力输出 Very low flow and pressure fluctuation.It can keep stable flow and pressure even it is low speed.

高压力设计,最高使用压力可达到35MPa It is high-pressure design.The highest pressure is 35MPa.

转速范围宽广,最高转速可达3000r/mim Rotation speed range is large.The highest rotation speed is 300R/Min.

可进行组合形成双联泵 It can be assembled to double pump.

对油液污染不敏感,使用寿命长 It is not sensitive to greasy dirt so that the lifetime is much longer.

可广泛适用于工业,如塑机、鞋机、压铸机械以及叉车等行业的液压系统。尤其适用于伺服变频驱动的节能系统 It is widely applied in industry,such as hydraulic system in plastic moulding machine,shoes machine,casting machine and forklift... Especially in system that servo variable-frequency drives.

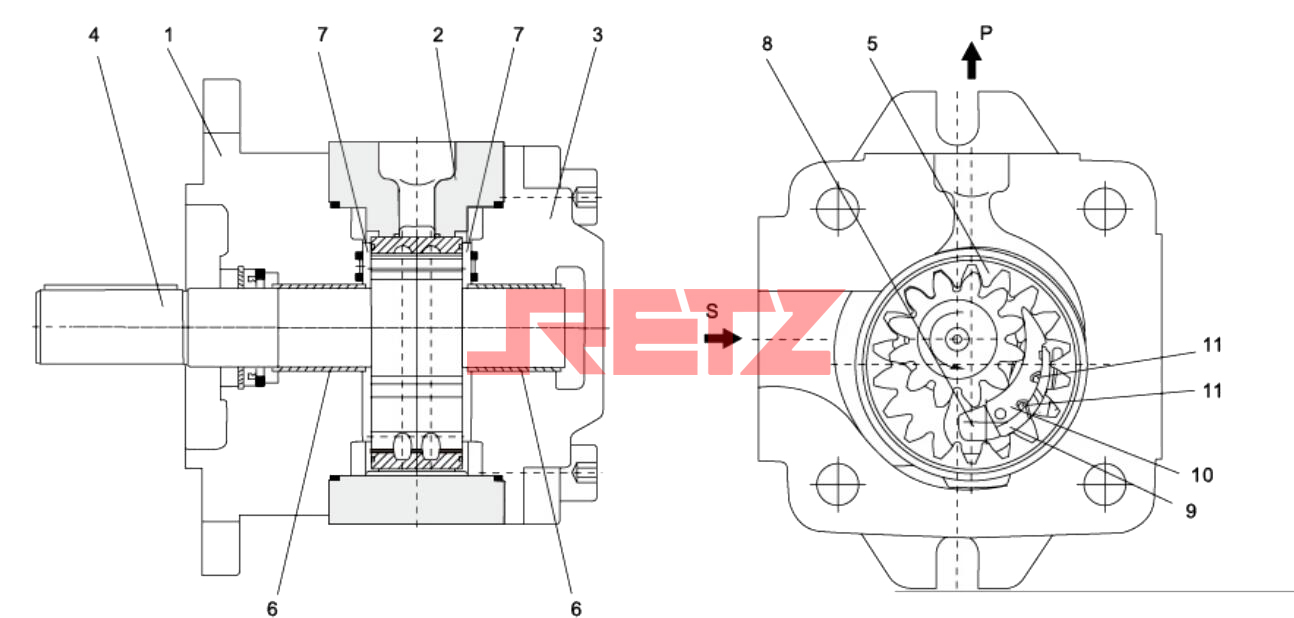

(RHG)进口内啮合齿轮泵 机能、剖面 Function and section

RHG系列液压泵为具有固定排量的间隙补偿的内啮齿轮泵 RHG series is an internal gear pump with backlash compensation and fixed displacemet.

其基本构成是∶前盖(1),泵体(2),后盖(3),齿轮轴(4),内齿圈(5),滑动轴承(6),前后侧板(7)和定位杆(8),以及由月牙副板(9),月牙主板(10)和塑料棒(11)组成的径向补偿功能。

Main Spare part:front cover(1)pump body(2)Rear cover(3),Gear shaft(4),Internal gear(5),ball bearing(6),Side plate(7),Locating Rod(8), and radial compensation by Filler segment carrier(),Filler sealing segment(10)and plastic bar(11).

型号说明 Model description

系列号 Series No | 规格Spec | 排量 mL/rDisplacementt | 工作压力MPaPressure | 转速范围 r/minRotation Speed | 重量KGWeight | ||

额定Rated | 最高Max | 最高Max | 最低Min | ||||

RHG0 | 10 | 10.2 | 31.5 | 35 | 3000 | 600 | 4.8 |

13 | 13.3 | 31.5 | 35 | 3000 | 600 | 4.9 | |

16 | 16 | 31.5 | 35 | 3000 | 600 | 5.2 | |

20 | 20 | 25 | 30 | 3000 | 600 | 5.6 | |

RHG1 | 25 | 25.3 | 31.5 | 35 | 3000 | 200 | 14.5 |

32 | 32.7 | 31.5 | 35 | 3000 | 200 | 15 | |

40 | 40.1 | 31.5 | 35 | 300 | 200 | 16 | |

50 | 50.7 | 31.5 | 35 | 3000 | 200 | 17 | |

63 | 63.7 | 25 | 30 | 3000 | 200 | 18.5 | |

RHG2 | 63 | 64.7 | 31.5 | 35 | 3000 | 200 | 42 |

80 | 81.4 | 31.5 | 35 | 3000 | 200 | 43.5 | |

100 | 100.2 | 31.5 | 35 | 3000 | 200 | 45.5 | |

125 | 125.3 | 31.5 | 35 | 3000 | 200 | 48 | |

145 | 145.2 | 25 | 28 | 3000 | 200 | 50 | |

160 | 162.8 | 21 | 26 | 3000 | 200 | 52 | |

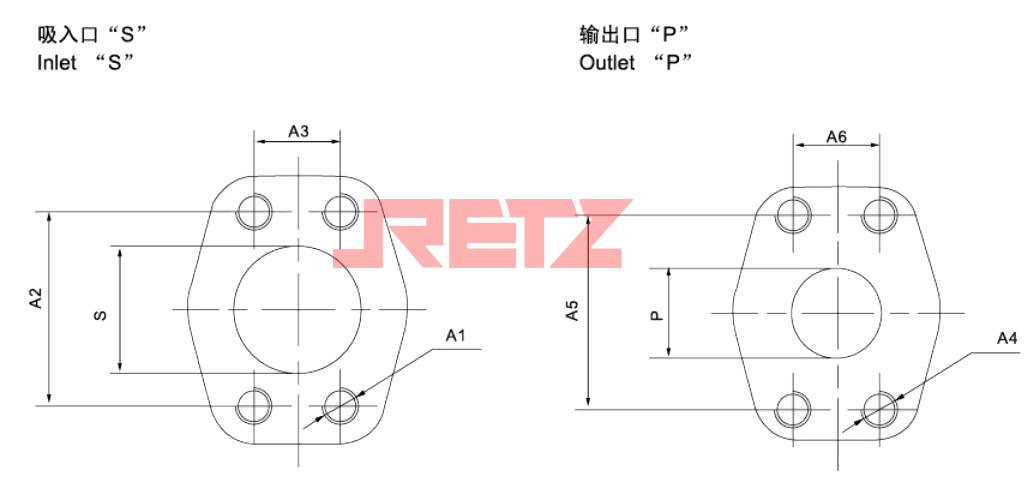

油口法兰连接尺寸 Inlet/Outlet flange

系列Model No. | 规格Spec | S | A1 | A2 | A3 | P | A4 | A5 | A6 |

RHG0 | 10 | φ19 | M10深15 M10 deep 15 | 52.4 | 26.2 | 13 | M8深13M8 deep 13 | 38.1 | 17.5 |

13 | |||||||||

16 | |||||||||

20 | φ26 | 58.7 | 30.2 | φ18 | M10深15M10 deep 15 | 47.6 | 22.2 | ||

RHG1 | 25 | φ32 | M10深17 M10 deep 17 | 58.7 | 30.2 | φ18 | M10深17 M10 deep 17 | 47.6 | 22.2 |

32 | |||||||||

40 | φ20 | 52.4 | 26.2 | ||||||

50 | |||||||||

63 | |||||||||

RHG2 | 63 | φ40 | M12深20 M12 deep 20 | 69.9 | 35.7 | φ23 | M10深17M 10 deep 17 | 52.4 | 26.2 |

80 | φ51 | 77.8 | 42.9 | φ32 | M12深20M12 deep 20 | 69.9 | 35.7 | ||

100 | |||||||||

125 | φ63.5 | 88.9 | 50.8 | φ38 | M16深25M16 deep 25 | 79.4 | 36.5 | ||

145 | |||||||||

160 | φ76 | M16深25 M16 deep 25 | 106.4 | 61.9 |

RHG双联内啮合齿轮泵

双联泵是由两个单泵串联组装而成,具有一个共用进油口和两个可以输向两个独立回路的出油口。按照两个泵的系列组合,可获得多种排量 Double pump is connected by two single pump,it is with the salme inlet and two outlet to two independent loop.With two pump connection,it get more different displacement.

RHG双联内啮合齿轮泵介绍

RHG10系列 RHG10 Series

RHG11系列 RHG11 Series

RHG21系列 RHG21 Series

RHG22系列 RHG22 Series

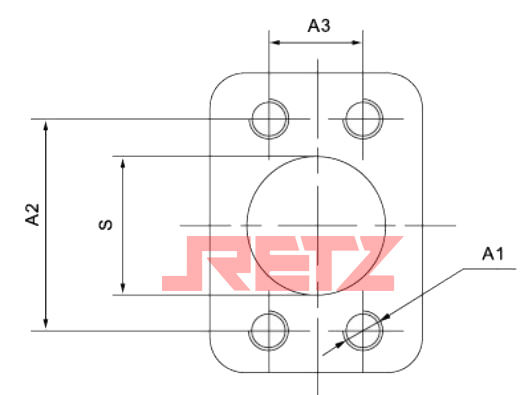

双联泵吸入口“S”Double pump Inlet“S”

系列 Series | S | A1 | A2 | A3 |

RHG10 | 中38 | M12深20 M12 Deep 20 | 69.9 | 35.7 |

RHG11 | φ51 | 77.8 | 42.9 | |

RHG21 | φ76 | M16深25 M16 Deep 25 | 106.4 | 61.9 |

RHG22 | φ89 | 120.7 | 69.9 |

使用注意事项Application

1、工作介质 Operating Oil

可使用粘度范围在10-300mm²/s的石油基矿物油,推荐使用ISO VG46抗磨液压油 Viscosity range:10-300mm2/s,ISOVG46 Anti-wearhydraulic oil is recommended for better performance.

2、工作温度 Operating Temperature

工作温度范围 -10℃-100℃,为保证长期的可靠寿命,最佳工作温度范围20℃-80℃ Operating temperature range:-10℃-100℃. To ensure the reliable lifetime,the best operating temperature range is20℃-80℃

3、清洁度控制 cleanliness control

要求控制系统油液的清洁度水平,不超过9级(NAS 1638)或17/14(ISO 4066)Control cleanliness of system oil,can not over 9 lever(NAS 1638)or 1714(ISO 4066)

4、泵安装 Installation

轴与电机连接尽可能使用挠性联轴器,以避免产生弯曲力矩或轴向推力,轴与电机轴最大允许同轴度误差小于0.15mm Shaft and motor should be connected by flexible coupling to avoid harmnful effects.Concentricity of shafts between pump and motor is important to pump life snd should be within 0.15mm

5、吸入口压力与配管 Pressure of Inlet and Pipline

允许吸入口绝对压力为0.2-2 Bar。合理的配管通径应不小于泵的吸油品,以确保平均0.6-1.2m/s的最佳吸油速度 Absolute pressure of inlet is 0.2-2Bar.Diameter of absorb pipline caln't be smaller than inlet to ensure the best average oil speed 0.6-1.2m/s.

6、进出口连接 Inlet/outlet connection

尽力避免进出油管采用钢管硬连接,建议使用橡胶软管,避免出现额外的负载导致额外的噪音 Rubber hose is recommended to avoid extra load causing extra noise.Don't connect with steel pipe.

7、维护 Maintenance

为提高泵的使用寿命,应定期检查系统的异常振动、噪音、油液温度、油箱内是泵有气泡生成以及有无泄漏等问题,并及时维护 In order to mke the life of pump longer,customer should check the systemin time,such as if abnormal shocking,noise,oil temperature,bubble in tank, leakage...and maintenance in time.

在线客服

在线客服