RETZ进口品质 活塞式蒸汽减压阀

简要描述:RETZ (活塞式)进口蒸汽减压阀采用高效先导阀式结构设计,准确且稳定地调整所需的二次蒸汽压力

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨 工况条件:减压

工况条件:减压 温度/压力:P-T:16bar-285℃

温度/压力:P-T:16bar-285℃ 更新时间:2022/08/22

更新时间:2022/08/22

(活塞式)进口蒸汽减压阀 主要技术参数及性能 Main technical parameters and performance

活塞式减压阀主要工作部件一曲面活塞及三重定位结构,在高速蒸汽汽流的冲击下,也能保证准确动作。相比于传统直边式活塞及双线定位的曲面活塞结构,最显著的优势是彻底解决了因活塞卡位、粘缸、拉缸现象而造成减压阀失效等常见问题,确保.阀后二次压力稳定 RETZ main working part of the piston type steam pressure reducing valve is a curved piston and a triple positioning structure, which can also ensure accurate action under the impact of high-speed steam flow. Compared with the traditional straight side piston and the double line positioning curved piston structure, the most significant advantage is that it completely solves the common problems such as the failure of the pressure reducing valve caused by the piston clamping, cylinder sticking and cylinder pulling, and ensures the stability of the secondary pressure behind the valve

规格说明 Description

导管设置方式 | 内置式 |

连接方式 | PN16/PN25 法兰 |

口径(mm) | F1/2-8” |

最大工作压差 | 16Bar |

人口压力范围 | 2-16Bar |

压力调整范围 | 10:1 |

最低差压 | 0.05MPa |

工作温度 | 285℃ |

最小可调整流量 | DN15~50额定流量的5% DN65-100:额定流量的10% |

注∶阀体压力为2.5MPa,工作压力为1.6MPa,压力偏差不大于±0.002MPa Note: the valve body pressure is 2.5MPa, the working pressure is 1.6Mpa, and the pressure deviation is not more than ± 0.002mpa

性能特点∶ Performance characteristics

1.独特的自润滑、排渣活塞结构设计,确保长效稳定控制 Unique self-lubricating and slag discharge piston structure design ensures long-term stable control

2.内置先导阀结构,即使在供汽负载不稳定,和后端设备用汽量变化较大时,其迅速响应的先导反馈信号,也可确保阀后二次压力非常稳定 Built in pilot valve structure, even when the steam supply load is unstable and the steam consumption of the back-end equipment changes greatly, the rapid response of the pilot feedback signal can ensure that the secondary pressure behind the valve is very stable

3.主阀与导阀的阀瓣阀座密封面,均采用抗冲蚀、抗磨损、耐腐蚀的Stellte硬质合金材料,并进行镜面加工处理阀芯内件均由不锈钢制成。以确保减压的长效控制,且更经久耐用 The sealing surfaces of the valve disc and valve seat of the main valve and the pilot valve are made of stellte hard alloy material with erosion resistance, abrasion resistance and corrosion resistance, and are mirror processed. The inner parts of the valve core are made of stainless steel. To ensure long-term control of pressure reduction and more durable

4.压力反馈平衡管为内置式结构,安装简单 Pressure feedback balance pipe is built-in structure, easy to install

5.独特的入口端,导阀内部和活塞下部(DN65以上口径)三重过滤单元,解决了杂质卡堵等常见问题 The unique inlet end, the inner part of the pilot valve and the lower part of the piston (diameter above DN65) triple filter unit solve common problems such as impurity blockage

6.减压比10∶1。当设定压力大于2barg且口径为DN65以上时,建议选用活塞式减压阀 The decompression ratio is 10:1. When the set pressure is greater than 2barg and the diameter is above DN65, it is recommended to select the piston type pressure reducing valve

材料表

序号 | 名称 | 材料 | 序号 | 名称 | 材料 |

1 | 主阀底板 | 铸钢 | 11 | 导瓣阀杆弹簧 | 不锈钢 |

2 | 底板密封垫 | 强化PTFE | 12 | 导阀阙杆 | 不锈钢+slellile |

3 | 主阀体 | 铸钢 | 13 | 导阀阀座 | 不锈钢+stellile |

4 | 主阀阀瓣 | 不锈钢+stellile | 14 | 导阀膜片 | 不锈钢 |

5 | 主阀阀座 | 不锈钢+strllile | 15 | 导阀上盖 | 铸钢 |

6 | 活塞 | 不锈钢 | 16 | 导阀主力弹簧 | 不锈钢弹簧 |

7 | 过滤网 | 不锈钢 | 17 | 导阀防护盖 | 铸钢 |

8 | 导阀连接板 | 铸钢 | 18 | 调压螺栓 | 铬钼钢 |

9 | 导阀阀体 | 铸钢 | 19 | 铭牌 | 不锈钢 |

10 | 导綢过滤网 | 不锈钢 |  | ||

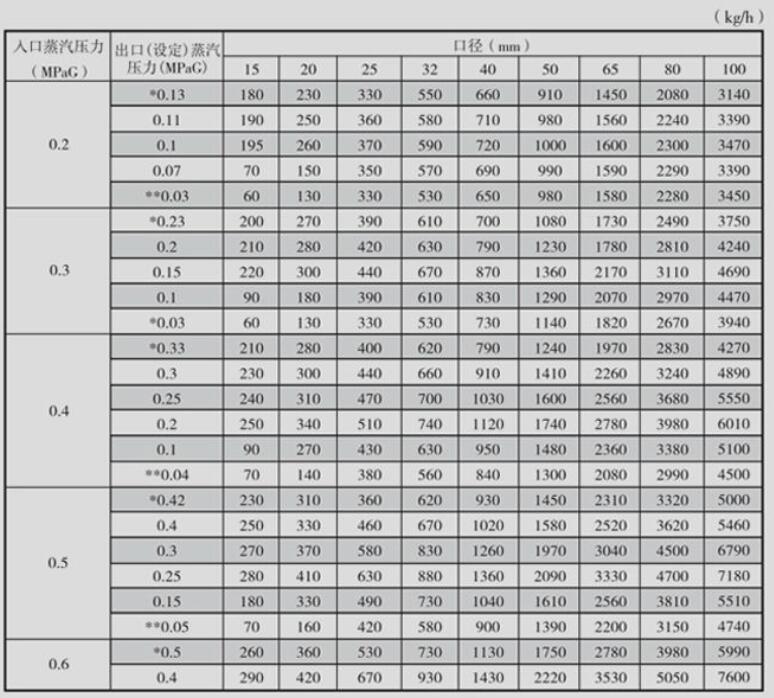

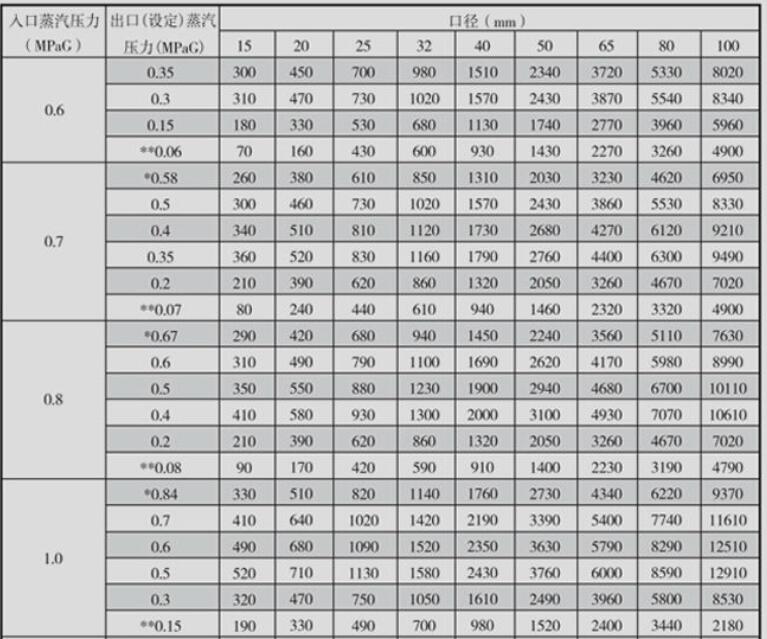

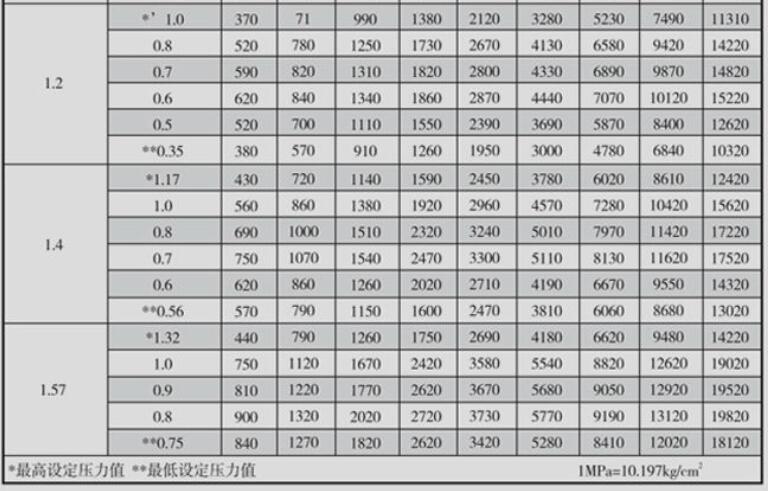

RETZ 活塞式蒸汽减压阀排量表 Displacement table of piston type steam pressure reducing valve

故障排除 Troubleshooting

故障 | 制造质量的原因 | 用户方面的原因 | 相应用户须知 |

减压阀直通失效 | 1.装配时不清洁 | 1.活塞卡住(在最高位置以下) 2.阀瓣或顶杆在导向套内卡住 3.阀瓣弹簧失去弹性 4.导阀泄漏或导阀瓣在孔内卡住 5.密封面间夹有导物或损坏6.膜破损,或其周边泄漏 7.阀后腔至膜片通道堵塞 | 1.活塞不破裂、气缸磨损应修理;应定期清洗,以免混入异物卡住 2.应及时卸下修理 3.更换弹簧 4.应定期清洗.控制通道应有过滤器 5.损坏的应修理或更换 6.定期换膜.周边密封处泄漏时应重新装配修理。 7.应解体清洗,可设阀前过滤器及排污管 |

阀门不通 | 1.装配时不清洁 | 1.活塞卡死在最高位置,(常见为异物、锈蚀等卡死) 2.阀前腔一导阀,导阀一活塞的小通道堵塞 3.弹簧失效,致使阀瓣不能打开 | 1.解体清洗和修理 2.应通清洗,通道应设过滤网 3.调整弹簧压紧力 |

阀后压力调不准 | 1.活塞密封不严2.装配质量差 | 1.弹簧疲劳失效 2.弹簧刚度过大 3.活动部件已磨损 4.膜片、薄膜已疲劳失效 | 1.更换弹簧 2.更换的弹簧应选用正确 3.应解体修理,装配要正确 4.应更换膜片、薄膜 |

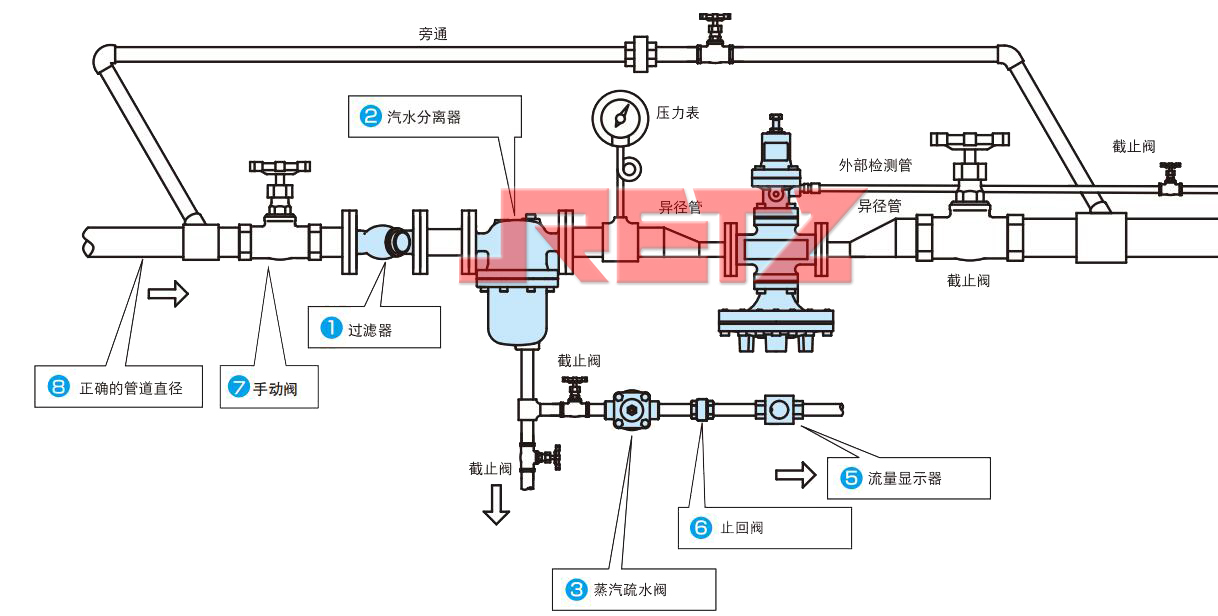

安装示意图 installation diagram

安装注意∶RETZ 减压阀前端必须安装100目过滤器 Installation note: a 100 mesh filter must be installed at the front end of the pressure reducing valve

在线客服

在线客服