RETZ进口品质 蒸汽喷射真空泵

简要描述:RETZ(水喷射器) 进口蒸汽喷射真空泵有一定压力的工作水蒸气通过拉瓦尔喷嘴,减压增速以超音速在吸入室与被抽介质混合,携带被抽介质一起向前运动,进入扩压管减速增压,排至下一级喷射器或大气,从而在吸入室形成真空。由于用户对真空度要求不同,每台蒸汽喷射真空泵可由单级或数级喷射器串接。级数越多,真空度越高(残压越低)

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨 工况条件:蒸汽喷射

工况条件:蒸汽喷射 温度/压力:P-T: 16bar@150℃

温度/压力:P-T: 16bar@150℃ 更新时间:2023/01/10

更新时间:2023/01/10

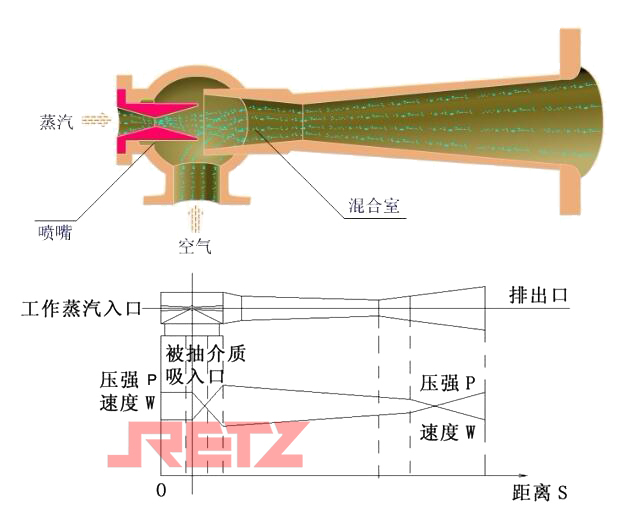

(水喷射器) 进口蒸汽喷射真空泵原理 principle

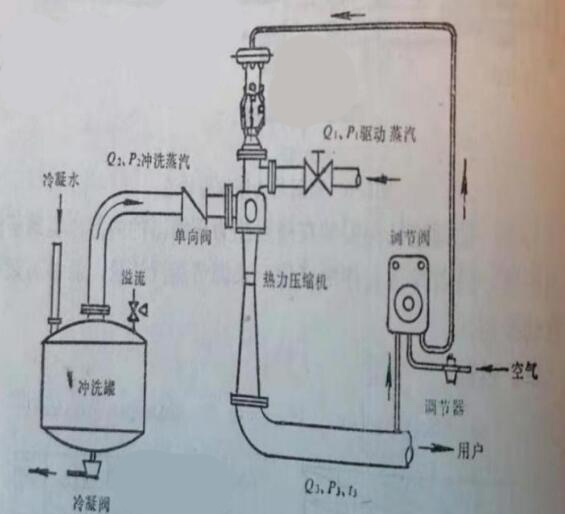

蒸汽喷射真空泵有一定压强的工作,蒸汽通过拉瓦尔喷咀,减压增速(蒸汽的势能转变为动能)以超音速喷入混合室,与被抽介质混合,进进行能量交换,混合后的气体进入扩压器,减速增压(动通转化为压强能),为了减少后级泵的抽气负荷,配置冷凝器,通过有一定温差的两种介质对流,进行热交换,达到冷凝高温介质目的,排到大气压。(原理见下图)retz品牌 The steam jet vacuum pump works at a certain pressure. The steam passes through the Laval nozzle, and the pressure reduction and speed increase (the potential energy of the steam is converted into kinetic energy) are injected into the mixing chamber at supersonic speed, mixed with the pumped medium, and energy exchange is carried out. The mixed gas enters the diffuser, and decelerates and pressurizes (the dynamic energy is converted into pressure energy). In order to reduce the pumping load of the later stage pump, a condenser is configured to convection through two kinds of media with a certain temperature difference, Conduct heat exchange to condense high-temperature medium and discharge it to atmospheric pressure. (See the figure below for the principle)

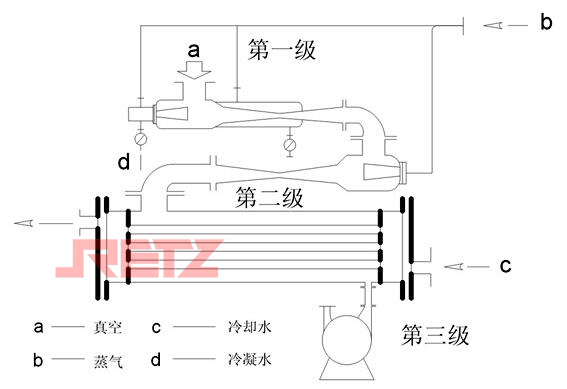

机组工作原理:

1.一级水蒸汽喷射真空泵连接到生产设备抽及其气体、蒸汽或气体并在泵内压缩到10mmhg左右 The primary steam jet vacuum pump is connected to the production equipment to extract its gas, steam or gas and compress it to about 10mmhg in the pump

2.二级水蒸汽喷射真空泵继续压缩上述工作介质到70mmhg然后排之气体引往列管冷凝器冷凝。冷凝后的液体进入下部三级水环泵抽吸,压缩后往大气中 The two-stage steam jet vacuum pump continues to compress the above working medium to 70mmhg, and then the discharged gas is led to the tube condenser for condensation. The condensed liquid enters the lower three-stage water ring pump for suction and is compressed into the atmosphere

操作 Operation

起动顺序 Starting sequence

1、把所有的截止阀和闸阀关闭 Close all stop valves and gate valves

2、蒸汽管道排污,排水,一直放出废气,供应饱和蒸汽,排污阀稍微打开一些 Steam pipe blowdown, drainage, exhaust gas is always discharged, saturated steam is supplied, and the blowdown valve is slightly opened

3、开启水环泵把供应泵用水阀打开,开启真空总管中截止阀,达到大约93、9毫巴 Open the water ring pump, open the water valve of the supply pump, and open the stop valve in the vacuum header to reach about 93,9 mbar

4、起动二级蒸汽喷射真空泵,喷嘴前输入蒸汽压力低不能低于3、5巴,高不能高于5巴 Start the secondary steam injection vacuum pump, and the input steam pressure in front of the nozzle shall not be lower than 3 or 5 bar, and the high pressure shall not be higher than 5 bar

5、起动一级蒸汽喷射真空泵,喷嘴前蒸汽压力不能低于3、5巴 Start the primary steam injection vacuum pump, and the steam pressure in front of the nozzle shall not be lower than 3 or 5 bar

6、所有喷射泵开启后,调节好冷凝器的进水阀,使它排出水温度不超过36℃ After all jet pumps are started, adjust the water inlet valve of the condenser to make its discharge water temperature not exceed 36 ℃

停机顺序 Shutdown sequence

1、关闭真空总阀 Close the main vacuum valve

2、关闭一级喷射泵汽阀 Close the steam valve of the primary injection pump

3、关闭二级喷射泵汽阀及蒸汽总阀 Close the steam valve and main steam valve of the secondary injection pump

4、放气停水环泵,关闭所有供水阀 Shut down the water ring pump and close all water supply valves

故障检查参考 Fault check reference

故障 | 转速过低 | 吸入管路泄露 | 工作液温度过高 | 工作液体过多 | 工作液体不足 | 机械密封过紧 | 联轴器不正 |

排汽量减少 | ● | ● | ● | ● | |||

噪音过大 | ● | ● | |||||

轴功率增大 | ● | ● | ● | ||||

过热 | ● | ● | ● | ● | |||

振动过大 | ● | ● | ● |

安装 Install

1、蒸汽喷射真空泵可以在室外露天安装。如果停工或在结冰气候时,整个装置能快速排水,因为已经装了内连管以备快速排水 The steam jet vacuum pump can be installed outdoors. In case of shutdown or freezing weather, the whole unit can drain water quickly, because the internal connecting pipe has been installed for rapid drainage

2、水环泵一定要有足够的静压,泵的填料箱一定有水封。在泵的排水管中装一个止回阀,以防止间歇或脉冲的空气回流。为了有效平衡冷凝器之间的压力差,管道封闭回路,一定要有合适的回路长道,好在每一条回路管的低位装一条放水管道,同时也可作为清洗冷凝器时出水口 The water ring pump must have enough static pressure, and the packing box of the pump must have a water seal. Install a check valve in the drain pipe of the pump to prevent intermittent or pulsed air backflow. In order to effectively balance the pressure difference between condensers, the pipeline must be closed, and there must be a proper circuit length, so that a drain pipe can be installed at the low position of each circuit pipe, and it can also be used as the water outlet for cleaning the condenser

3、安装蒸汽管道时,需注意尽量要使送到喷嘴的蒸汽尽可能干燥,从蒸汽分离器到喷射泵之间带保温。蒸汽管道越短越好,分离器应该长期保持干燥,为此接到喷射泵的蒸汽管一定要从蒸汽主管道上端接出温蒸汽不但腐蚀喷嘴和过早扩散,而且严重影响小喷嘴口的功能。由于要求高真空度,以及尤其泵内小喷嘴口径,所以一定要检查装在蒸汽过滤器与喷射泵内蒸汽喷嘴之间的气管是否干净。蒸汽喷射泵装上所谓进汽小气箱,可以很方便把喷嘴拆下来,用一支探针直觉检查喷嘴通路。蒸汽垫圈不要偏心放置,以免影响蒸汽自由流动截面积 When installing the steam pipe, it is necessary to make the steam sent to the nozzle as dry as possible, and there is thermal insulation between the steam separator and the jet pump. The shorter the steam pipe is, the better. The separator should be kept dry for a long time. Therefore, the steam pipe connected to the jet pump must be connected with warm steam from the upper end of the main steam pipe, which not only corrodes the nozzle and diffuses prematurely, but also seriously affects the function of the small nozzle. Due to the requirement of high vacuum and the small nozzle diameter in the pump, it is necessary to check whether the air pipe installed between the steam filter and the steam nozzle in the jet pump is clean. The steam injection pump is installed with the so-called small inlet gas box, which can easily remove the nozzle and intuitively check the nozzle path with a probe. The steam gasket shall not be placed eccentrically to avoid affecting the free flow sectional area of steam

在线客服

在线客服