RETZ进口品质 WG鼓形齿式联轴器

简要描述:RETZ进口鼓形齿式联轴器(WG)径向尺寸小,承载能力大,常用于低速重载工况条件的轴系传动,并经动平衡的齿式联轴器可用于高速传动,如燃汽轮机的轴系传动

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨 工况条件:联接机械

工况条件:联接机械 温度/压力:710-1250000N.m.

温度/压力:710-1250000N.m. 更新时间:2023/03/27

更新时间:2023/03/27

进口鼓形齿式联轴器(WG) 产品用途 Product use

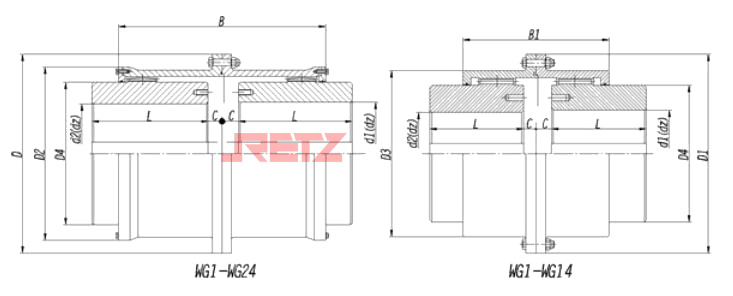

WG鼓形齿式联轴器即为将外齿制成球面,球面中心在齿轮轴线上,齿侧间隙较一般齿轮大,WG鼓形齿式联轴器相对于直齿联轴器来说可允许大的角位移,可齿的接触条件,提高传递转矩的能力,延长使用寿命,具有角位移时沿齿宽的接触状态,由齿数相同的内齿圈和带外齿的凸缘半联轴器等零件组成。WG鼓形齿式联轴器分为I型和II型两种形式,WG鼓形齿式联轴器I型为带压盖型,适用于WG1-WG24,优点在于拆卸压板即可检验、换外齿;缺点是制作工序叫为复杂重量大价格高。WG鼓形齿式联轴器II型为不带压盖型,适用于WG1-WG14,优点是价格便宜。

WG drum gear couplings are designed to make external teeth into a spherical surface, with the spherical center on the gear axis, and the backlash between the teeth is larger than that of ordinary gears. WG drum gear couplings can allow large angular displacement compared to straight gear couplings, improve tooth contact conditions, improve the ability to transmit torque, extend service life, and have a contact state along the tooth width during angular displacement. They are composed of internal gear rings with the same number of teeth, flange half couplings with external teeth, and other components. WG drum tooth type couplings are divided into two types: Type I and Type II. Type I of WG drum tooth type couplings is a type with a gland, which is suitable for WG1-WG24. The advantage is that the pressing plate can be disassembled to inspect and replace the external teeth; The disadvantage is that the manufacturing process is called complex, heavy, and expensive. WG drum gear coupling type II is a non gland type, suitable for WG1-WG14, with the advantage of low cost.

基本参数 Basic parameters and dimensions

号 | 额定 转矩 N·m | 许用 转速 rpm | 轴孔直径 d1、d2、dz | 轴孔长度L | D | D1 | D2 | D3 | D4 | B | B1 | C | 转动惯量 kg·m2 | 重量kg | ||||

Y | J1、Z1 | Ⅰ | Ⅱ | Ⅰ | Ⅱ | Ⅰ | Ⅱ | |||||||||||

WG1 | 710 | 7500 | 12,14 | 32 | — | 122 | 115 | 98 | 88 | 60 | 116 | 100 | 30 | — | 0.008 | 0.0063 | 5.6 | 4.86 |

16,18,19 | 42 | — | 20 | 14 | ||||||||||||||

20,22,24 | 52 | — | 10 | 4 | ||||||||||||||

25,28 | 62 | 44 | 3 | 3 | ||||||||||||||

30,32,35,38 | 82 | 60 | 3 | 3 | ||||||||||||||

40,42 | 112 | 84 | 3 | 3 | ||||||||||||||

WG2 | 1250 | 6700 | 22,24 | 52 | — | 150 | 145 | 118 | 108 | 77 | 136 | 104 | 20 | 4 | 0.021 | 0.016 | 9.78 | 7.48 |

25,28 | 62 | — | 10 | 3 | ||||||||||||||

30,32,35,38 | 82 | 60 | 3 | 3 | ||||||||||||||

40,42,45,48, 50,55,56 | 112 | 84 | 3 | 3 | ||||||||||||||

WG3 | 2500 | 6300 | 22,24 | 52 | — | 170 | 165 | 140 | 125 | 90 | 160 | 108 | 33 | 7 | 0.047 | 0.033 | 16.7 | 12.2 |

25,28 | 62 | — | 23 | 3 | ||||||||||||||

30,32,35,38 | 82 | 60 | 3 | 3 | ||||||||||||||

40,42,45,48, 50,55,56 | 112 | 84 | 3 | 3 | ||||||||||||||

60,63 | 142 | 107 | 3 | 3 | ||||||||||||||

WG4 | 4500 | 5600 | 30,32,35,38 | 82 | — | 200 | 195 | 160 | 145 | 112 | 180 | 116 | 13 | 3 | 0.098 | 0.073 | 25.6 | 19.6 |

40,42,45,48, 50,55,56 | 112 | 84 | 3 | 3 | ||||||||||||||

60,63,65, 70,71,75 | 142 | 107 | 3 | 3 | ||||||||||||||

80 | 172 | 132 | 3 | 3 | ||||||||||||||

WG5 | 7100 | 5300 | 30,32,35,38 | 82 | — | 225 | 215 | 180 | 168 | 128 | 200 | 126 | 23 | 3 | 0.175 | 0.126 | 35 | 26.1 |

40,42,45,48, 50,55,56 | 112 | 84 | 3 | 3 | ||||||||||||||

60,63,65, 70,71,75 | 142 | 107 | 3 | 3 | ||||||||||||||

80,85,90 | 172 | 132 | 3 | 3 | ||||||||||||||

WG6 | 10000 | 5000 | 30,32,35,38 | 82 | — | 245 | 230 | 200 | 185 | 145 | 224 | 134 | 35 | 3 | 0.295 | 0.213 | 51.6 | 38 |

40,42,45,48, 50,55,56 | 112 | — | 5 | 5 | ||||||||||||||

60,63,65, 70,71,75 | 142 | 107 | 5 | 5 | ||||||||||||||

80,85,90,95 | 172 | 132 | 5 | 5 | ||||||||||||||

100 | 212 | 167 | 5 | 5 | ||||||||||||||

WG7 | 14000 | 4500 | 32,35,38 | 82 | — | 272 | 265 | 230 | 210 | 160 | 224 | 148 | 45 | 5 | 0.53 | 0.35 | 68.6 | 45 |

40,42,45,48, 50,55,56 | 112 | — | 15 | 5 | ||||||||||||||

60,63,65, 70,71,75 | 142 | 107 | 5 | 5 | ||||||||||||||

80,85,90,95 | 172 | 132 | 5 | 5 | ||||||||||||||

100,110 | 212 | 167 | 5 | 5 | ||||||||||||||

WG8 | 20000 | 4250 | 55,56 | 112 | — | 290 | 272 | 245 | 225 | 176 | 272 | 162 | 29 | 5 | 0.71 | 0.46 | 79.5 | 55.8 |

60,63,65,70, 71,75 | 142 | 107 | 5 | 5 | ||||||||||||||

80,85,90,95 | 172 | 132 | 5 | 5 | ||||||||||||||

100,110, 120,125 | 212 | 167 | 5 | 5 | ||||||||||||||

WG9 | 25000 | 4000 | 65,70,71,75 | 142 | 107 | 315 | 305 | 265 | 245 | 190 | 280 | 176 | 5 | 5 | 1.05 | 0.77 | 106.5 | 80.5 |

80,85,90,95 | 172 | 132 | 5 | 5 | ||||||||||||||

100,110,120, 125 | 212 | 167 | 5 | 5 | ||||||||||||||

130,140 | 252 | 202 | 5 | 5 | ||||||||||||||

WG10 | 40000 | 3550 | 75 | 142 | — | 355 | 340 | 300 | 280 | 225 | 330 | 196 | 28 | 5 | 1.87 | 1.54 | 158.8 | 121.8 |

80,85,90,95 | 172 | 132 | 5 | 5 | ||||||||||||||

100,110,120, 125 | 212 | 167 | 5 | 5 | ||||||||||||||

130,140,150 | 252 | 202 | 5 | 5 | ||||||||||||||

160 | 302 | 242 | 5 | 5 | ||||||||||||||

WG11 | 56000 | 3000 | 85,90,95 | 172 | — | 412 | 385 | 345 | 325 | 256 | 360 | 224 | 15 | 8 | 3.66 | 2.77 | 214 | 167 |

110,110,120, 125 | 212 | 167 | 8 | 8 | ||||||||||||||

130,140,150 | 252 | 202 | 8 | 8 | ||||||||||||||

160,170,180 | 302 | 242 | 8 | 8 | ||||||||||||||

额定 转矩 N·m | 许用 转速 rpm | 轴孔直径 d1、d2、dz | 轴孔长度L | D | D1 | D2 | D3 | D4 | B | B1 | C | 转动惯量 kg·m2 | 重量kg | |||||

Y | J1、Z1 | Ⅰ | Ⅱ | Ⅰ | Ⅱ | Ⅰ | Ⅱ | |||||||||||

WG12 | 80000 | 2800 | 120,125 | 212 | 167 | 440 | 435 | 375 | 360 | 288 | 414 | 250 | 8 | 8 | 6.39 | 4.75 | 302 | 142 |

130,140,150 | 252 | 202 | 8 | 8 | ||||||||||||||

160,170,180 | 302 | 242 | 8 | 8 | ||||||||||||||

190,200 | 352 | 282 | 8 | 8 | ||||||||||||||

WG13 | 112000 | 2500 | 140,150 | 252 | 202 | 490 | 480 | 425 | 400 | 320 | 470 | 272 | 8 | 8 | 10.44 | 7.76 | 390 | 309 |

160,170,180 | 302 | 242 | 8 | 8 | ||||||||||||||

190,200,220 | 352 | 282 | 8 | 8 | ||||||||||||||

WG14 | 160000 | 2300 | 160,170,180 | 302 | 242 | 545 | 540 | 462 | 440 | 362 | 530 | 316 | 10 | 10 | 17.46 | 13.52 | 522 | 423 |

190,200,220 | 352 | 282 | 10 | 10 | ||||||||||||||

240,250,260 | 410 | 330 | 10 | 10 | ||||||||||||||

WG15 | 224000 | 2100 | 160,170,180 | 302 | 242 | 580 | — | 488 | — | 400 | 560 | — | 10 | — | 24.91 | — | 677 | — |

190,200,220 | 352 | 282 | 10 | — | ||||||||||||||

240,250,260 | 410 | 330 | 10 | — | ||||||||||||||

270 | 470 | 380 | 10 | — | ||||||||||||||

WG16 | 280000 | 1900 | 180 | 302 | 242 | 650 | — | 560 | — | 440 | 600 | — | 12 | — | 43.22 | — | 939 | — |

190,200,220 | 352 | 282 | 12 | — | ||||||||||||||

240,250,260 | 410 | 330 | 12 | — | ||||||||||||||

280,300 | 470 | 380 | 12 | — | ||||||||||||||

WG17 | 355000 | 1800 | 200,220 | 352 | 282 | 690 | — | 600 | — | 460 | 650 | — | 12 | — | 56.27 | — | 1041 | — |

240,250,260 | 410 | 330 | 12 | — | ||||||||||||||

280,300,320 | 470 | 380 | 12 | — | ||||||||||||||

WG18 | 450000 | 1700 | 220 | 352 | 282 | 750 | — | 650 | — | 510 | 700 | — | 12 | — | 88.17 | — | 1381 | — |

240,250,260 | 410 | 330 | 12 | — | ||||||||||||||

280,300,320 | 470 | 380 | 12 | — | ||||||||||||||

340,360 | 550 | 450 | 12 | — | ||||||||||||||

WG19 | 560000 | 1600 | 240,250,260 | 410 | 330 | 775 | — | 690 | — | 535 | 745 | — | 12 | — | 108.8 | — | 1526 | — |

280,300,320 | 470 | 380 | 12 | — | ||||||||||||||

340,360,380 | 550 | 450 | 12 | — | ||||||||||||||

WG20 | 710000 | 1500 | 260 | 410 | 330 | 825 | — | 730 | — | 580 | 785 | — | 14 | — | 164.4 | — | 2081 | — |

280,300,320 | 470 | 380 | 14 | — | ||||||||||||||

340,360,380 | 550 | 450 | 14 | — | ||||||||||||||

400 | 650 | 540 | 14 | — | ||||||||||||||

WG21 | 800000 | 1300 | 280,300,320 | 470 | 380 | 925 | — | 825 | — | 620 | 810 | — | 14 | — | 242.7 | — | 2460 | — |

340,360,380 | 550 | 450 | 14 | — | ||||||||||||||

400,420,440 | 650 | 540 | 14 | — | ||||||||||||||

WG22 | 900000 | 950 | 320 | 470 | 380 | 950 | — | 850 | — | 665 | 820 | — | 14 | — | 297 | — | 2775 | — |

340,360,380 | 550 | 450 | 14 | — | ||||||||||||||

400,420,440, 450,460 | 650 | 540 | 14 | — | ||||||||||||||

WG23 | 1000000 | 900 | 360,380 | 550 | 450 | 1030 | — | 900 | — | 710 | 880 | — | 14 | — | 384.8 | — | 3148 | — |

400,420,440, 450,460,480, 500 | 650 | 540 | 14 | — | ||||||||||||||

WG24 | 1250000 | 850 | 380 | 550 | 450 | 1060 | — | 925 | — | 730 | 900 | — | 16 | — | 477.8 | — | 3766 | — |

400,420,440, 450,460,480, 500 | 650 | 540 | 16 | — | ||||||||||||||

520 | 800 | 680 | 16 | — | ||||||||||||||

注:必须在容许值的范围内使用该联轴器 Note: The coupling must be used within the allowable range

在线客服

在线客服