RETZ进口品质 WGT接中间套鼓形齿式联轴器

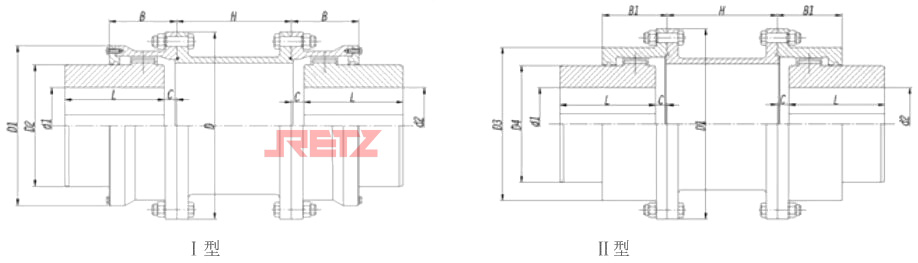

简要描述:RETZ进口接中间套鼓形齿式联轴器(WGT)属于鼓形齿式联轴器的一种简称“鼓齿联轴器”,分为I型和II型两种形式,I型为带压盖型,优点在于拆卸压板即可检验、换外齿;II型为不带压盖型

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨 工况条件:联接机械

工况条件:联接机械 温度/压力:710-1250000N.m.

温度/压力:710-1250000N.m. 更新时间:2023/03/27

更新时间:2023/03/27

进口带制动盘齿式联轴器(WGP) 产品用途 Product use

1.WGT接中间套鼓形齿式联轴器是齿式联轴器的改进型,相对于直齿联轴器来说可允许大的角位移,可齿的接触条件,提高传递转矩的能力,延长使用寿命,具有角位移时沿齿宽的接触状态,由齿数相同的内齿圈和带外齿的凸缘半联轴器等零件组成

WGT intermediate sleeve drum type gear coupling is an improved type of gear coupling, which allows for large angular displacement compared to straight tooth couplings, improves tooth contact conditions, improves the ability to transmit torque, extends service life, and has a contact state along the tooth width during angular displacement. It is composed of internal gear rings with the same number of teeth, flange half couplings with external teeth, and other components

2.接中间套鼓形齿式联轴器在工作时,两轴产生相对角位移,内外齿的齿面周期性作轴向相对滑动,必然形成齿面磨损和功率消耗,因此,齿式联轴器需在有良好和密封的状态下工作。齿式联轴器径向尺寸小,承载能力大,常用于低速重载工况条件的轴系传动,并经动平衡的齿式联轴器可用于高速传动

During operation of the intermediate sleeve drum type gear coupling, relative angular displacement occurs between the two shafts, and the tooth surfaces of the inner and outer teeth periodically slide axially relative to each other, inevitably resulting in tooth surface wear and power consumption. Therefore, the gear coupling needs to operate in a good and sealed state. Toothed couplings have small radial dimensions and large load carrying capacity, and are commonly used for shafting transmission under low speed and heavy load conditions. Dynamically balanced tooth couplings can be used for high-speed transmission

基本参数 Basic parameters and dimensions

号 | 额定 转矩 N·m | 轴孔 直径 d1、d2 | 轴孔长度L | D | D1 | D2 | D3 | D4 | B | B1 | H min | C | 转动惯量 kg·m2 | 重量kg | ||||

Y | J1 | Ⅰ | Ⅱ | Ⅰ | Ⅱ | Ⅰ | Ⅱ | |||||||||||

WGT1 | 710 | 12,14 | 32 | — | 122 | 115 | 98 | 88 | 60 | 58 | 50 | 75 | 30 | — | 0.008 | 0.0063 | 5.66 | 4.86 |

16,18,19 | 42 | — | 20 | 14 | ||||||||||||||

20,22,24 | 52 | — | 10 | 4 | ||||||||||||||

25,28 | 62 | 44 | 3 | 3 | ||||||||||||||

30,32,35,38 | 82 | 60 | ||||||||||||||||

40,42 | 112 | 84 | ||||||||||||||||

WGT2 | 1250 | 22,24 | 52 | — | 150 | 145 | 118 | 108 | 77 | 68 | 52 | 80 | 20 | 4 | 0.021 | 0.016 | 9.78 | 7.48 |

25,28 | 62 | — | 10 | 3 | ||||||||||||||

30,32,35,38 | 82 | 60 | 3 | |||||||||||||||

40,42,45,48, 50,55,56 | 112 | 84 | ||||||||||||||||

WGT3 | 2500 | 22,24 | 52 | — | 170 | 165 | 140 | 125 | 90 | 80 | 54 | 80 | 33 | 7 | 0.047 | 0.033 | 16.7 | 12.2 |

25,28 | 62 | — | 23 | 3 | ||||||||||||||

30,32,35,38 | 82 | 60 | 3 | |||||||||||||||

40,42,45,48, 50,55,56 | 112 | 84 | ||||||||||||||||

60,63 | 142 | 107 | ||||||||||||||||

WGT4 | 4500 | 30,32,35,38 | 82 | — | 200 | 195 | 160 | 145 | 112 | 90 | 58 | 100 | 13 | 3 | 0.098 | 0.073 | 25.6 | 19.6 |

40,42,45,48, 50,55,56 | 112 | 84 | 3 | |||||||||||||||

60,63,65, 70,71,75 | 142 | 107 | ||||||||||||||||

80 | 172 | 132 | ||||||||||||||||

WGT5 | 7100 | 30,32,35,38 | 82 | — | 225 | 215 | 180 | 168 | 128 | 100 | 63 | 100 | 23 | 3 | 0.175 | 0.126 | 35 | 26.1 |

40,42,45,48, 50,55,56 | 112 | 84 | 3 | |||||||||||||||

60,63,65, 70,71,75 | 142 | 107 | ||||||||||||||||

80,85,90 | 172 | 132 | ||||||||||||||||

WGT6 | 10000 | 30,32,35,38 | 82 | — | 245 | 230 | 200 | 185 | 145 | 112 | 67 | 100 | 35 | 5 | 0.295 | 0.213 | 51.6 | 38 |

40,42,45,48, 50,55,56 | 112 | — | 5 | |||||||||||||||

60,63,65, 70,71,75 | 142 | 107 | ||||||||||||||||

80,85,90,95 | 172 | 132 | ||||||||||||||||

100 | 212 | 167 | ||||||||||||||||

WGT7 | 14000 | 32,35,38 | 82 | — | 272 | 265 | 230 | 210 | 160 | 122 | 74 | 120 | 45 | 5 | 0.53 | 0.35 | 68.6 | 45 |

40,42,45,48, 50,55,56 | 112 | — | 15 | |||||||||||||||

60,63,65, 70,71,75 | 142 | 107 | 5 | |||||||||||||||

80,85,90,95 | 172 | 132 | ||||||||||||||||

100,110 | 212 | 167 | ||||||||||||||||

WGT8 | 20000 | 55,56 | 112 | — | 290 | 272 | 245 | 225 | 176 | 136 | 81 | 120 | 29 | 5 | 0.71 | 0.46 | 79.5 | 55.8 |

60,63,65,70, 71,75 | 142 | 107 | 5 | |||||||||||||||

80,85,90,95 | 172 | 132 | ||||||||||||||||

100,110, 120,125 | 212 | 167 | ||||||||||||||||

号 | 额定 转矩 N·m | 轴孔 直径 d1、d2 | 轴孔长度L | D | D1 | D2 | D3 | D4 | B | B1 | H min | C | 转动惯量 kg·m2 | 重量kg | ||||

Y | Y | Ⅰ | Ⅱ | Ⅰ | Ⅱ | Ⅰ | Ⅱ | |||||||||||

WGT9 | 25000 | 65,70,71,75 | 142 | 107 | 315 | 305 | 265 | 245 | 190 | 140 | 88 | 155 | 5 | 5 | 1.05 | 0.77 | 106.5 | 80.5 |

80,85,90,95 | 172 | 132 | ||||||||||||||||

100,110,120, 125 | 212 | 167 | ||||||||||||||||

130,140 | 252 | 202 | ||||||||||||||||

WGT 10 | 40000 | 75 | 142 | — | 355 | 340 | 300 | 280 | 225 | 165 | 98 | 155 | 28 | 5 | 1.87 | 1.54 | 158.8 | 121.8 |

80,85,90,95 | 172 | 132 | 5 | |||||||||||||||

100,110,120, 125 | 212 | 167 | ||||||||||||||||

130,140,150 | 252 | 202 | ||||||||||||||||

160 | 302 | 242 | ||||||||||||||||

WGT 11 | 56000 | 85,90,95 | 172 | — | 412 | 385 | 345 | 325 | 256 | 180 | 112 | 175 | 15 | 8 | 3.71 | 2.82 | 216.6 | 169.6 |

110,110,120, 125 | 212 | 167 | 8 | |||||||||||||||

130,140,150 | 252 | 202 | ||||||||||||||||

160,170,180 | 302 | 242 | ||||||||||||||||

WGT 12 | 80000 | 120,125 | 212 | 167 | 440 | 435 | 375 | 360 | 288 | 210 | 125 | 205 | 8 | 8 | 6.48 | 4.84 | 305.3 | 245.3 |

130,140,150 | 252 | 202 | ||||||||||||||||

160,170,180 | 302 | 242 | ||||||||||||||||

190,200 | 352 | 282 | ||||||||||||||||

WGT 13 | 112000 | 140,150 | 252 | 202 | 490 | 480 | 425 | 400 | 320 | 235 | 136 | 205 | 8 | 8 | 10.58 | 7.9 | 394.5 | 313.5 |

160,170,180 | 302 | 242 | ||||||||||||||||

190,200,220 | 352 | 282 | ||||||||||||||||

WGT 14 | 160000 | 160,170,180 | 302 | 242 | 545 | 540 | 462 | 440 | 362 | 265 | 158 | 240 | 10 | 10 | 17.72 | 13.78 | 529.5 | 430.5 |

190,200,220 | 352 | 282 | ||||||||||||||||

240,250,260 | 410 | 330 | ||||||||||||||||

WGT 15 | 224000 | 160,170,180 | 302 | 242 | 580 | — | 488 | — | 400 | 280 | — | 240 | 10 | — | 25.25 | — | 684.5 | — |

190,200,220 | 352 | 282 | ||||||||||||||||

240,250,260 | 410 | 330 | ||||||||||||||||

280 | 470 | 380 | ||||||||||||||||

WGT 16 | 280000 | 180 | 302 | 242 | 650 | — | 560 | — | 440 | 300 | — | 240 | 12 | — | 43.7 | — | 948.2 | — |

190,200,220 | 352 | 282 | ||||||||||||||||

240,250,260 | 410 | 330 | ||||||||||||||||

280,300 | 470 | 380 | ||||||||||||||||

WGT 17 | 355000 | 200,220 | 352 | 282 | 690 | — | 600 | — | 460 | 325 | — | 280 | 12 | — | 57.37 | — | 1059 | — |

240,250,260 | 410 | 330 | ||||||||||||||||

280,300,320 | 470 | 380 | ||||||||||||||||

WGT 18 | 450000 | 220 | 352 | 282 | 750 | — | 650 | — | 510 | 350 | — | 280 | 12 | — | 59.37 | — | 1399 | — |

240,250,260 | 410 | 330 | ||||||||||||||||

280,300,320 | 470 | 380 | ||||||||||||||||

340,360 | 550 | 450 | ||||||||||||||||

WGT 19 | 560000 | 240,250,260 | 410 | 330 | 775 | — | 690 | — | 535 | 372 | — | 350 | 12 | — | 110.2 | — | 1544 | — |

280,300,320 | 470 | 380 | ||||||||||||||||

340,360,380 | 550 | 450 | ||||||||||||||||

WGT 20 | 710000 | 260 | 410 | 330 | 825 | — | 730 | — | 580 | 392.5 | — | 350 | 14 | — | 166.1 | — | 2099 | — |

280,300,320 | 470 | 380 | ||||||||||||||||

340,360,380 | 550 | 450 | ||||||||||||||||

400 | 650 | 540 | ||||||||||||||||

WGT 21 | 800000 | 280,300,320 | 470 | 380 | 925 | — | 825 | — | 620 | 405 | — | 350 | 14 | — | 242.7 | — | 2482 | — |

340,360,380 | 550 | 450 | ||||||||||||||||

400,420,440 | 650 | 540 | ||||||||||||||||

WGT 22 | 900000 | 320 | 470 | 380 | 950 | — | 850 | — | 665 | 410 | — | 400 | 14 | — | 299.2 | — | 2797 | — |

340,360,380 | 550 | 450 | ||||||||||||||||

400,420,440, 450,460 | 650 | 540 | ||||||||||||||||

WGT 23 | 1000000 | 360,380 | 550 | 450 | 1030 | — | 900 | — | 710 | 440 | — | 400 | 14 | — | 388.8 | — | 3183 | — |

400,420,440, 450,460,480, 500 | 650 | 540 | ||||||||||||||||

WGT 24 | 1250000 | 380 | 550 | 450 | 1060 | — | 925 | — | 730 | 450 | — | 400 | 16 | — | 482 | — | 3801 | — |

400,420,440, 450,460,480, 500 | 650 | 540 | ||||||||||||||||

520 | 800 | 680 | ||||||||||||||||

注:

1、质量与转动惯量是按最大轴孔直径的Y型轴孔计算的近似值,未计算中间套 The mass and rotational inertia are approximate values calculated based on the Y-shaped shaft hole with the largest shaft hole diameter, and the intermediate sleeve is not calculated

2、联轴器的许用转速见下页,应按照中间套的长度和重量验算临界转速 The allowable rotational speed of the coupling is shown on the next page, and the critical rotational speed should be checked and calculated based on the length and weight of the intermediate sleeve

联轴器许用转速与中间套的重量、转动惯量 Allowable rotational speed of coupling, weight and rotational inertia of intermediate sleeve

联轴器型号 | 许用转速 r/min | Hmin mm | 重量 kg | 转动惯量 kg·m2 | 中间套每加长10mm的重量kg | 中间套每加长10mm的转动惯量 kg·m2 | ||||

Ⅰ | Ⅱ | Ⅰ | Ⅱ | Ⅰ | Ⅱ | Ⅰ | Ⅱ | |||

WGT1 | 7500 | 75 | 1.58 | 1.47 | 0.0032 | 0.0028 | 0.088 | 0.08 | 0.00011 | 0.000088 |

WGT2 | 6700 | 80 | 2.68 | 2.4 | 0.082 | 0.0079 | 0.13 | 0.125 | 0.00022 | 0.00021 |

WGT3 | 6300 | 80 | 3.5 | 3.1 | 0.015 | 0.0136 | 0.16 | 0.16 | 0.00041 | 0.00038 |

WGT4 | 5600 | 100 | 5.2 | 5.2 | 0.032 | 0.031 | 0.2 | 0.19 | 0.0008 | 0.00071 |

WGT5 | 5300 | 100 | 6 | 5.8 | 0.048 | 0.042 | 0.23 | 0.22 | 0.0012 | 0.001 |

WGT6 | 5000 | 100 | 6.6 | 6.1 | 0.061 | 0.053 | 0.26 | 0.24 | 0.0017 | 0.0013 |

WGT7 | 4500 | 120 | 10.5 | 8.6 | 0.134 | 0.105 | 0.32 | 0.3 | 0.003 | 0.0027 |

WGT8 | 4250 | 120 | 11.5 | 9 | 0.164 | 0.117 | 0.32 | 0.3 | 0.003 | 0.0043 |

WGT9 | 4000 | 155 | 15.7 | 13.8 | 0.25 | 0.209 | 0.42 | 0.4 | 0.0045 | 0.006 |

WGT10 | 3500 | 155 | 22.2 | 15.3 | 0.46 | 0.294 | 0.46 | 0.45 | 0.0064 | 0.009 |

WGT11 | 3000 | 175 | 28.5 | 20.9 | 0.82 | 0.53 | 0.52 | 0.5 | 0.0091 | 0.014 |

WGT12 | 2800 | 205 | 37.3 | 30.8 | 1.21 | 0.81 | 0.71 | 0.7 | 0.015 | 0.023 |

WGT13 | 2500 | 205 | 46.4 | 39.4 | 1.94 | 1.56 | 0.83 | 0.8 | 0.024 | 0.035 |

WGT14 | 2300 | 240 | 66.4 | 52.2 | 3.49 | 2.62 | 0.96 | 0.95 | 0.037 | — |

WGT15 | 2100 | 240 | 73.4 | — | 4.42 | — | 1.03 | — | 0.044 | — |

WGT16 | 1900 | 240 | 95.1 | — | 6.88 | — | 1.5 | — | 0.072 | — |

WGT17 | 1800 | 280 | 132.4 | — | 10.78 | — | 2.5 | — | 0.16 | — |

WGT18 | 1700 | 280 | 158.9 | — | 15.62 | — | 2.76 | — | 0.22 | — |

WGT19 | 1600 | 350 | 182.4 | — | 19.3 | — | 2.96 | — | 0.27 | — |

WGT20 | 1500 | 350 | 203.1 | — | 24.7 | — | 3.16 | — | 0.32 | — |

WGT21 | 1300 | 350 | 261.6 | — | 38.1 | — | 4.2 | — | 0.5 | — |

WGT22 | 950 | 400 | 304.6 | — | 47.7 | — | 4.47 | — | 0.59 | — |

WGT23 | 900 | 400 | 391.6 | — | 70.9 | — | 5.77 | — | 0.88 | — |

WGT24 | 850 | 400 | 412 | — | 78 | — | 6.07 | — | 1.02 | — |

在线客服

在线客服