RETZ进口品质 GL滚子链联轴器

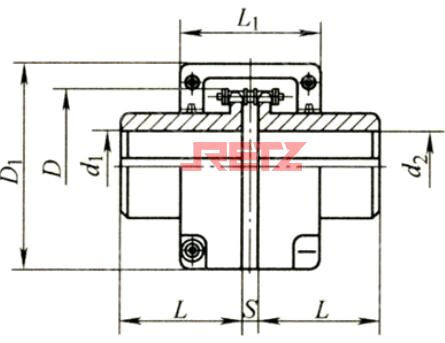

简要描述:RETZ进口滚子链联轴器(GL)主要由一条链条及两链轮式半联轴器组成。一条公用的链条同时与两个齿数相同的并列链轮啮合,实现了两半联轴器的联接

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨 工况条件:联接机械

工况条件:联接机械 温度/压力:40-25000N.m.

温度/压力:40-25000N.m. 更新时间:2023/03/29

更新时间:2023/03/29

进口滚子链联轴器(GL) 产品用途 Product use

1、应用于纺织、农机、起重运输、工程、矿山、轻工、化工等机械的轴系传动 Applied to shaft transmission of machinery such as textile, agricultural machinery, lifting and transportation, engineering, mining, light industry, chemical industry, etc

2、适用于高温、潮湿和多尘工况环境,不适用高速、有剧烈冲击载荷和传递轴向力的场合 Suitable for high temperature, humidity, and dusty working conditions, not suitable for high-speed, severe impact loads, and transmission of axial forces

3、离心力过大会加速各元件间的磨损和发热,不宜用于很高速度的传动,且由于缓冲,吸振能力差,不宜在频繁启动和强烈冲击下工作 Excessive centrifugal force can accelerate the wear and heat between various components, and is not suitable for high speed transmissions. Due to poor cushioning and vibration absorption capabilities, it is not suitable for working under frequent starts and strong shocks

4、成本低,适用于高温潮湿和多尘工况环境 Low cost, suitable for high-temperature, humid, and dusty environments

5、不适用高速、有剧烈冲击载荷和传递轴向力的场合 Not suitable for situations with high speed, severe impact loads, and transmission of axial force

结构特点 Structural features

1、利用公用链条同时与两个齿数相同的并列链轮啮合,以实现两半联轴器联结 Use a common chain to simultaneously engage two parallel sprockets with the same number of teeth to achieve coupling between the two halves

2、结构简单、装卸方便;拆卸时不用移动被联结的两轴 Simple structure and convenient loading and unloading; There is no need to move the connected two shafts during disassembly

3、尺寸紧凑,质量轻,有一定的补偿能力,对安装要求精度不高 Compact size, light weight, certain compensation capability, and low installation accuracy requirements

4、两轴许用相对径向位移为:当用双排链时,△y=0.02p(p为链条节距);当用单排时,△y为0.05~1.2mm;许用相对角位移△a不大于1°

基本参数 Basic parameters and dimensions

型号 | 公称扭矩N·m | 许用转速 rpm | 轴孔直径d1、d2 | 轴孔长度L | 链号 | 链条节距P | 齿数Z | D | S | DK max | LK max | 重量kg | 转动惯量kg·m2 | 许用补偿量 | ||||

不装罩壳 | 安装罩壳 | Y型 | J1型 | 径向 | 轴向 | 角向 | ||||||||||||

L | L1 | mm | mm | mm | ° | |||||||||||||

GL1 | 40 | 1400 | 4500 | 16 | 42 | — | 06B | 9.525 | 14 | 51.06 | 4.9 | 70 | 70 | 0.4 | 0.0001 | 0.19 | 1.4 | 1 |

18 | 42 | — | ||||||||||||||||

19 | 42 | — | ||||||||||||||||

20 | 52 | 38 | ||||||||||||||||

GL2 | 63 | 1250 | 4500 | 19 | 42 | — | 06B | 9.525 | 16 | 57.08 | 4.9 | 75 | 75 | 0.7 | 0.0002 | 0.19 | 1.4 | 1 |

20 | 52 | 38 | ||||||||||||||||

22 | 52 | 38 | ||||||||||||||||

24 | 52 | 38 | ||||||||||||||||

GL3 | 100 | 1000 | 4000 | 20 | 52 | 38 | 08B | 12.7 | 14 | 68.88 | 6.7 | 85 | 80 | 1.1 | 0.00086 | 0.25 | 1.9 | 1 |

22 | 52 | 38 | ||||||||||||||||

24 | 52 | 38 | ||||||||||||||||

25 | 60 | 44 | ||||||||||||||||

GL4 | 160 | 1000 | 4000 | 24 | 52 | — | 08B | 12.7 | 16 | 76.91 | 6.7 | 95 | 88 | 1.8 | 0.00086 | 0.25 | 1.9 | 1 |

25 | 62 | 44 | ||||||||||||||||

28 | 62 | 44 | ||||||||||||||||

30 | 82 | 60 | ||||||||||||||||

32 | 82 | 60 | ||||||||||||||||

GL5 | 250 | 800 | 3150 | 28 | 62 | — | 10A | 15.875 | 16 | 94.46 | 9.2 | 112 | 100 | 3.2 | 0.0025 | 0.32 | 2.3 | 1 |

30 | 82 | 60 | ||||||||||||||||

32 | 82 | 60 | ||||||||||||||||

35 | 82 | 60 | ||||||||||||||||

38 | 82 | 60 | ||||||||||||||||

40 | 112 | 84 | ||||||||||||||||

GL6 | 400 | 630 | 2500 | 32 | 82 | 60 | 10A | 15.875 | 20 | 116.57 | 9.2 | 140 | 105 | 5 | 0.0058 | 0.32 | 2.3 | 1 |

35 | 82 | 60 | ||||||||||||||||

38 | 82 | 60 | ||||||||||||||||

40 | 112 | 84 | ||||||||||||||||

42 | 112 | 84 | ||||||||||||||||

45 | 112 | 84 | ||||||||||||||||

48 | 112 | 84 | ||||||||||||||||

50 | 112 | 84 | ||||||||||||||||

GL7 | 630 | 630 | 2500 | 40 | 112 | 84 | 12A | 19.05 | 18 | 137.78 | 10.9 | 150 | 122 | 7.4 | 0.012 | 0.38 | 2.8 | 1 |

42 | 112 | 84 | ||||||||||||||||

45 | 112 | 84 | ||||||||||||||||

48 | 112 | 84 | ||||||||||||||||

50 | 112 | 84 | ||||||||||||||||

55 | 112 | 84 | ||||||||||||||||

60 | 142 | 107 | ||||||||||||||||

GL8 | 1000 | 500 | 2240 | 45 | 112 | 84 | 16A | 25.4 | 16 | 154.33 | 14.3 | 180 | 135 | 11.1 | 0.025 | 0.5 | 3.8 | 1 |

48 | 112 | 84 | ||||||||||||||||

50 | 112 | 84 | ||||||||||||||||

55 | 112 | 84 | ||||||||||||||||

60 | 142 | 107 | ||||||||||||||||

65 | 142 | 107 | ||||||||||||||||

70 | 142 | 107 | ||||||||||||||||

GL9 | 1600 | 400 | 2000 | 50 | 112 | 84 | 16A | 25.4 | 20 | 186.5 | 14.3 | 215 | 145 | 20 | 0.061 | 0.5 | 3.8 | 1 |

55 | 112 | 84 | ||||||||||||||||

60 | 142 | 107 | ||||||||||||||||

65 | 142 | 107 | ||||||||||||||||

70 | 142 | 107 | ||||||||||||||||

75 | 142 | 107 | ||||||||||||||||

80 | 172 | 132 | ||||||||||||||||

GL10 | 2500 | 315 | 1600 | 60 | 142 | 107 | 20A | 31.75 | 18 | 213.02 | 17.8 | 245 | 165 | 26.1 | 0.079 | 0.63 | 4.7 | 1 |

65 | 142 | 107 | ||||||||||||||||

70 | 142 | 107 | ||||||||||||||||

75 | 142 | 107 | ||||||||||||||||

80 | 172 | 132 | ||||||||||||||||

85 | 172 | 132 | ||||||||||||||||

90 | 172 | 132 | ||||||||||||||||

GL11 | 4000 | 250 | 1500 | 75 | 142 | 107 | 24A | 38.1 | 16 | 231.49 | 21.5 | 270 | 195 | 39.2 | 0.188 | 0.76 | 5.7 | 1 |

80 | 172 | 132 | ||||||||||||||||

85 | 172 | 132 | ||||||||||||||||

90 | 172 | 132 | ||||||||||||||||

95 | 172 | 132 | ||||||||||||||||

100 | 212 | 167 | ||||||||||||||||

GL12 | 6300 | 250 | 1250 | 85 | 172 | 132 | 28A | 44.45 | 16 | 270.08 | 24.9 | 310 | 205 | 59.4 | 0.38 | 0.88 | 6.6 | 1 |

90 | 172 | 132 | ||||||||||||||||

95 | 172 | 132 | ||||||||||||||||

100 | 212 | 167 | ||||||||||||||||

110 | 212 | 167 | ||||||||||||||||

120 | 212 | 167 | ||||||||||||||||

GL13 | 10000 | 200 | 1120 | 100 | 212 | 167 | 32A | 50.8 | 18 | 340.8 | 28.6 | 380 | 230 | 86.5 | 0.86 | 1 | 7.6 | 1 |

110 | 212 | 167 | ||||||||||||||||

120 | 212 | 167 | ||||||||||||||||

125 | 212 | 167 | ||||||||||||||||

130 | 252 | 202 | ||||||||||||||||

140 | 252 | 202 | ||||||||||||||||

GL14 | 16000 | 200 | 1000 | 120 | 212 | 167 | 32A | 50.8 | 22 | 405.22 | 28.6 | 450 | 250 | 150.8 | 2.06 | 1 | 7.6 | 1 |

125 | 212 | 167 | ||||||||||||||||

130 | 252 | 202 | ||||||||||||||||

140 | 252 | 202 | ||||||||||||||||

150 | 252 | 202 | ||||||||||||||||

160 | 302 | 242 | ||||||||||||||||

GL15 | 25000 | 200 | 900 | 140 | 252 | 202 | 40A | 63.5 | 20 | 466.25 | 35.6 | 510 | 285 | 234.4 | 4.37 | 1.27 | 9.5 | 1 |

150 | 252 | 202 | ||||||||||||||||

160 | 302 | 242 | ||||||||||||||||

170 | 302 | 242 | ||||||||||||||||

180 | 302 | 242 | ||||||||||||||||

190 | 352 | 282 | ||||||||||||||||

注:表中联轴器重量、转动惯量是近似值 Note: The weight and rotational inertia of the coupling in the table are approximate values.

在线客服

在线客服