RETZ进口品质 持压泄压阀 紧急开启阀

简要描述:RETZ进口泄压持压阀、紧急开启阀可用于高层大楼消防试循环系统的泄压使用以防止水压过高造成系统危险,主要用于供水系统的理想产品

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨  工况条件:泄压持压阀

工况条件:泄压持压阀 温度/压力:P-T: 25bar@100℃

温度/压力:P-T: 25bar@100℃ 更新时间:2023/04/14

更新时间:2023/04/14

产品描述 Product Description

进口泄压持压阀、紧急开启阀在传动方式上采用了水力操作并能自动控制,即利用控制管路中的压差自动开合,关闭主阀,使上游的压力不超过某一设定值。阀体采用了全通道流线型设计,流体阻力小,密封性能好,自动启闭性能灵敏。该阀的主要特点是既可以作泄压阀,又可以作持压阀。

The imported pressure relief and emergency opening valves adopt hydraulic operation and can be automatically controlled in transmission mode, that is, use the pressure difference in the control pipeline to automatically open and close, close the main valve, and ensure that the upstream pressure does not exceed a certain set value. The valve body adopts the full channel streamline design, with small fluid resistance, good sealing performance, and sensitive automatic opening and closing performance. The main feature of this valve is that it can be used as both a pressure relief valve and a pressure holding valve.

1.作泄压阀时:可将水管中超过先导阀安全设定值的压力释放,并维持管中压力于一定安全值以下,以防止管中高压或突压毁坏管线设备

When using a pressure relief valve: it can release the pressure in the water pipe that exceeds the safety setting value of the pilot valve, and maintain the pressure in the pipe below a certain safety value to prevent high pressure or sudden pressure in the pipe from damaging pipeline equipment

2.作持压阀时:可维持主阀上游供水压力于某一设定直以上,以保障主阀上游的供水压力

When acting as a pressure holding valve, it can maintain the upstream water supply pressure of the main valve above a certain set point to ensure the upstream water supply pressure of the main valve

3.作紧急开启阀时:装于消防喷淋泵出水口处,当泵出水口处压力上升某一设定值以上立即开启

When acting as an emergency opening valve: installed at the outlet of the fire sprinkler pump, immediately open when the pressure at the pump outlet rises above a certain set value

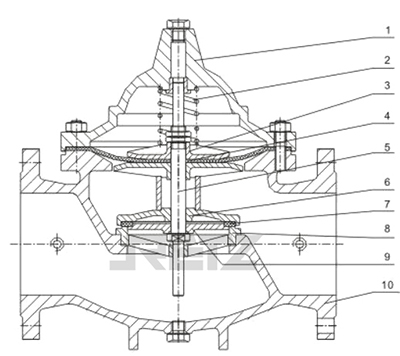

结构和主要零件材质 Structure and main component materials

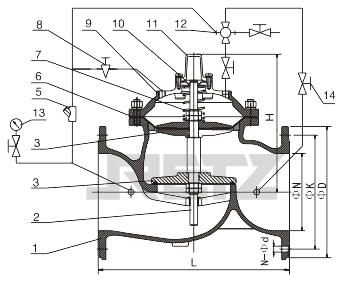

泄压持压阀、紧急开启阀由主阀、导阀、针阀、球阀、压力表等组成,按不同通径分有膜片和活塞式。由于导阀、针阀、球阀和压力表等要用外接导管与主阀连接,所以统称为导管控制系统

The pressure relief and holding valve and emergency opening valve are composed of main valve, pilot valve, needle valve, ball valve, pressure gauge, etc. They are divided into diaphragm and piston types according to different diameters. Due to the use of external conduits to connect guide valves, needle valves, ball valves, and pressure gauges to the main valve, they are collectively referred to as conduit control systems

主要零件材质 Main component materials

编号No. | 零件名称Name | 主 要 材 质Material |

1 | 阀盖 | 灰铸铁、球墨铸铁、碳素钢、不锈钢 |

2 | 压缩弹簧 | 硅锰钢、铬钒钢、不锈钢 |

3 | 膜片压板 | 黄铜、碳素钢、球墨铸铁 |

4 | 膜片 | 丁晴橡胶 |

5 | 阀杆 | 不锈钢 |

6 | 阀板 | 黄铜、碳素钢、球墨铸铁 |

7 | 密封圈 | 丁晴橡胶 |

8 | 阀座 | 黄铜、不锈钢、碳素钢 |

9 | 阀板压板 | 黄铜、碳素钢、球墨铸铁 |

10 | 阀体 | 灰铸铁、球墨铸铁、碳素钢、不锈钢 |

工作原理 working principle

泄压/特压阀安装在泄水旁路上,即与主管道并联安装。只要上游压力低于导阀设定值,导阀12关闭,上游压力作用在主阀的膜片 上方,使主阀维持关闭。一旦上游压力逐渐上升到超过导阀12设定值的压力,导阀12就会开启,泄放主阀膜片上方的压力水,此时主阀开启,大量泄水降压至设定值时,才缓慢平稳关闭,不产生二次水锤。适用于消除因流量供大于需而逐渐增大过高压力,如(消防初期)消火栓系统、自动喷淋系统(水泵出口处)作泄压阀时,球阀一般为关闭,必要时把球阀打开。作持压阀时球阀为常闭或用丝堵换下。

上方,使主阀维持关闭。一旦上游压力逐渐上升到超过导阀12设定值的压力,导阀12就会开启,泄放主阀膜片上方的压力水,此时主阀开启,大量泄水降压至设定值时,才缓慢平稳关闭,不产生二次水锤。适用于消除因流量供大于需而逐渐增大过高压力,如(消防初期)消火栓系统、自动喷淋系统(水泵出口处)作泄压阀时,球阀一般为关闭,必要时把球阀打开。作持压阀时球阀为常闭或用丝堵换下。

The pressure relief/special pressure valve is installed on the drainage bypass, which is parallel to the main pipeline. As long as the upstream pressure is lower than the set value of the pilot valve, pilot valve 12 closes, and the upstream pressure acts on the diaphragm of the main valve, keeping the main valve closed. Once the upstream pressure gradually rises above the set value of pilot valve 12, pilot valve 12 will open and release the pressure water above the main valve diaphragm. At this time, the main valve will open, and a large amount of water will be released and depressurized to the set value before slowly and smoothly closing, without generating a secondary water hammer. Suitable for eliminating excessive pressure gradually increasing due to excessive flow supply. For example, in the early stages of fire protection, when the fire hydrant system and automatic sprinkler system (at the outlet of the water pump) are used as pressure relief valves, the ball valve is generally closed, and if necessary, the ball valve is opened. When working as a pressure holding valve, the ball valve should be normally closed or replaced with a plug.The hydraulic control valves are powered by the upstream and downstream pressure difference △ P, controlled by the pilot valve, allowing the diaphragm (piston) to operate under hydraulic differential, and are completely automatically adjusted by hydraulic pressure, thereby making the main valve disc fully open or fully closed, or in a regulated state. Fully closed state: When the water pressure at the inlet end of the main valve enters the valve body and control room respectively, and the ball valve outside the main valve is closed at the same time, the main valve is in a fully closed state; Fully open state: When the ball valve outside the main valve is fully open, all the water pressure in the control room is discharged to the atmosphere or downstream low-pressure area, so the main valve is in a fully open state; Floating state: Adjust the opening of the ball valve outside themain valve to balance the water flow between the needle valve and the ball valve. At this time, the main valve is in a floating state. (This is the working principle of the diaphragm type, and the same applies to the piston type.)

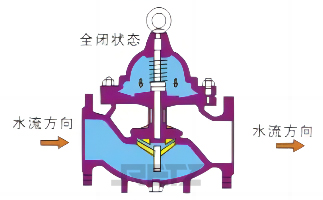

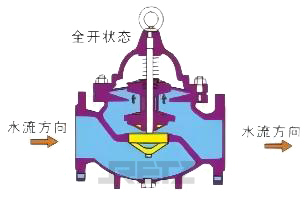

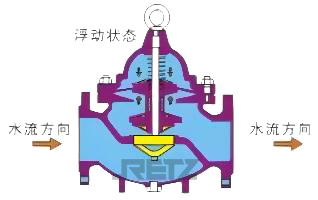

水力控制阀都是上下游压力差△P为动力,由导阀控制,使膜片(活塞)在液压差动下操作,完全由水力自动调节,从而使主阀阀瓣完全开启或完全关闭,或处于调节状态。全闭状态:当主阀进口端水压分别进入阀体及控制室,且主阀外部的球阀同时关闭,此时主阀处于全闭状态;全开状态:当主阀外部的球阀全开后,此时控制室内水压全部被排到大气或下游低压区,所以主阀呈现全开状态;浮动状态:调节主阀外部的球阀开度,使水流经过针阀与球阀的水流达到平衡,此时主阀处于浮动状态。

The hydraulic control valves are powered by the upstream and downstream pressure difference △ P, controlled by the pilot valve, allowing the diaphragm (piston) to operate under hydraulic differential, and are completely automatically adjusted by hydraulic pressure, thereby making the main valve disc fully open or fully closed, or in a regulated state. Fully closed state: When the water pressure at the inlet end of the main valve enters the valve body and control room respectively, and the ball valve outside the main valve is closed at the same time, the main valve is in a fully closed state; Fully open state: When the ball valve outside the main valve is fully open, all the water pressure in the control room is discharged to the atmosphere or downstream low-pressure area, so the main valve is in a fully open state; Floating state: Adjust the opening of the ball valve outside the main valve to balance the water flow between the needle valve and the ball valve. At this time, the main valve is in a floating state.

全关闭状态:当主阀进口端水压分别进入阀体及控制室,且主阀的外部球阀同时关闭,此时主阀处于关闭状态。

Fully closed state: When the water pressure at the inlet end of the main valve enters the valve body and control room respectively, and the external ball valve of the main valve is closed at the same time, the main valve is in a fully closed state

全开启状态:当主阀外部的球阀全开后,此时控制室内水压全部释放到管路下游,而主阀也呈现为开启状态。

Fully open state: When the ball valve outside the main valve is fully open, all the water pressure in the control room is released to the downstream of the pipeline, and the main valve also shows a fully open state

浮动调节状态:调节主阀外部的球阀开度,使进水端流向控制室的水流和控制室流向下游的水流达到平衡,此时主阀处于调节浮动状态。

Floating adjustment state: Adjust the opening of the ball valve outside the main valve to balance the water flow from the inlet end to the control room and the water flow from the control room to the downstream. At this time, the main valve is in the floating adjustment state

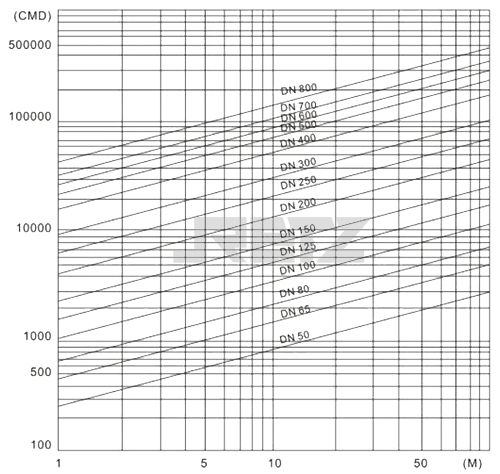

流量示意图 Flow diagram

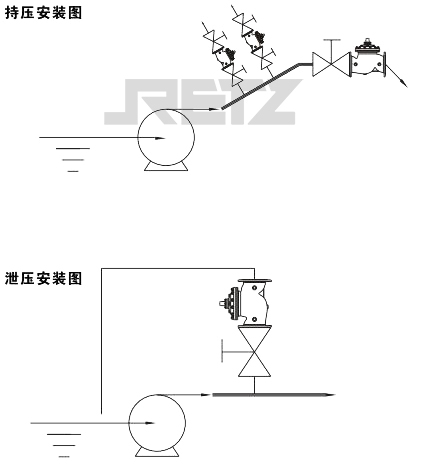

安装与调试 Installation and debugging

1、主阀最佳安装方式是水平卧式安装在泄水旁路上,阀盖朝上,其它安装方式也可达到操作功能,安装前彻底清除管道内的杂物,要注意主阀体流向箭头,遵循方向安装。安装后应确保没有管路应力作用在阀体及阀内部件上。

2、对重要给水管路应安装旁通阀。排水口最好通向大气或完全敞开,如出口接管会影响泄水能力;为防止泄水时伤及人员和设备,则出口接管应将泄水引至安全排水的地方

3、主阀前应装一只闸阀和一只过流器,主阀后可不装闸阀。

4、球阀接在下水管道上,球阀一般为关闭,必要时把球阀打开,泄放主阀隔膜上方的压力水,此时主阀阀盘呈现全开状态,大量向下游泄水,结束后把球阀关闭,恢复泄水降压。其他球阀全部打开。

5、导阀与导管控制系统已于出厂前装配和调整完毕,如导阀出厂设定值不适合现场要求,可作如下调正,先松开导阀手轮下的锁紧螺母,然后顺时针拧动导阀手轮为增加压力,反之为降低压力,调好后锁紧螺母。同时要调节针阀开度,使水流经过针阀与导阀的水流达到平衡,此时更佳地泄水降压。(顺时针拧动针阀手轮为减少开度,逆时针为增加开度。)

6、通水前的须冲洗管路系统。

7、外接管路过滤器要求定期清洗

8、重要管路要求安装旁通阀。

在线客服

在线客服