RETZ进口品质 隔膜式水力遥控浮球阀

简要描述:RETZ进口隔膜式水力遥控浮球阀用于高层建筑和工矿企业的水箱、水池及水塔的自动供水系统,可控制水箱或水池液面,当水池水位达到预定水位时,阀门自动关闭;水位下降时,阀门自动开启补水

品牌:RETZ美国瑞茨

品牌:RETZ美国瑞茨  工况条件:液位控制

工况条件:液位控制 温度/压力:P-T: 25bar@100℃

温度/压力:P-T: 25bar@100℃ 更新时间:2023/04/16

更新时间:2023/04/16

产品描述 Product Description

进口隔膜式水力遥控浮球阀主要安装工况企业、民用建筑等领域的各种水池、水塔进水口处,当水池达到预设定水位时,浮球导阀控制主阀自动关闭,进水口停止供水;水位下降时,阀门自动开启补水The imported diaphragm type hydraulic remote control floating ball valve is mainly installed at the inlet of various water tanks and towers in industries such as enterprises and civil buildings. When the water tank reaches the pre-set water level, the floating ball guide valve controls the main valve to automatically close, and the water supply at the inlet stops; When the water level drops, the valve automatically opens to replenish water

其特点如下:Its characteristics are as follows

1、关闭严密可靠。采用衬胶阀瓣密封,利用液压控制原理,使阀瓣关闭力成正比,密封可靠性高 Close tightly and reliably. Adopting rubber lined valve disc sealing, utilizing hydraulic control principle to make the valve disc closing force proportional, with high sealing reliability

2、过流量大。采用半直线型流道宽阀体和等过流量面积设计,阀门阻力小 Excessive flow. Adopting a semi linear flow channel with wide valve body and equal flow area design, the valve has low resistance

3、运行安全,关闭速度可调,阀门动作平稳,启闭不产生压力波动,无管振和噪音 Safe operation, adjustable closing speed, stable valve action, no pressure fluctuations during opening and closing, no pipe vibration or noise

4、使用维护方便。主阀体可安装在水池外面,调试检查方便,维护简单 Easy to use and maintain. The main valve body can be installed outside the water tank, making debugging and inspection convenient and maintenance simple

工作原理 working principle

主阀安装在水池外,浮球导阀安装在水箱内,当水位降低时,浮球导阀打开,阀盖的控制室压力卸掉,则主阀开启向水池供水:当水位上升时,浮球导阀关闭,阀盖的控制室压力增加,则主阀关闭停止向水池供水。

The main valve is installed outside the water tank, and the floating ball guide valve is installed inside the water tank. When the water level drops, the floating ball guide valve opens, and the control room pressure of the valve cover is relieved. The main valve opens to supply water to the water tank. When the water level rises, the floating ball guide valve closes, and the control room pressure of the valve cover increases. The main valve closes to stop supplying water to the water tank.

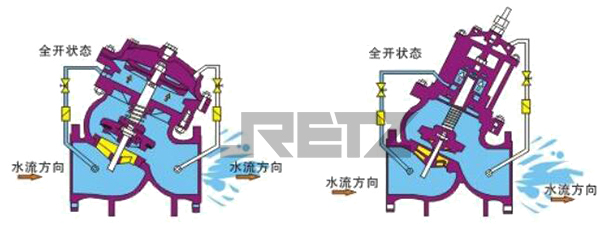

全开状态 Fully open state

当水泵启动后,阀门进水口压力上升,压力水一方面推动主阀板开启,另一方面通过导管系统进入膜片(活塞)下腔,而膜片(活塞)上腔的水通过导管系统泄入压力低的阀门出水口,而阀门在二合力的作用下缓慢开启。

After the water pump starts, the pressure at the valve inlet rises. On the one hand, the pressure water pushes the main valve plate open, and on the other hand, it enters the lower chamber of the diaphragm (piston) through the conduit system. The water in the upper chamber of the diaphragm (piston) is discharged into the outlet of the low pressure valve through the conduit system, and the valve slowly opens under the combined force of the two forces

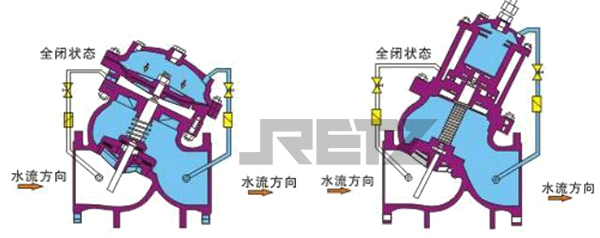

全闭状态 Fully closed state

当水泵停机后,阀门中的水流速度降低,在接于近零时,主阀板在弹簧力和自身重力作用下快速关闭,而阀后的压力水通过导管系统返回膜片(活塞)上腔,并推动固定阀杆上的小阀板缓慢关闭。

After the water pump stops, the water flow velocity in the valve decreases. When it is close to zero, the main valve plate quickly closes under the action of spring force and self gravity, while the pressure water behind the valve returns to the upper chamber of the diaphragm (piston) through the conduit system and pushes the small valve plate on the fixed valve rod to slowly close.

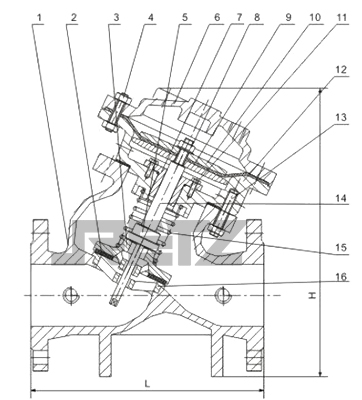

结构和主要零件材质 Structure and main component materials

隔膜式水力遥控浮球阀分二种型式: 膜片式与活塞式。结构由主阀、过滤器、针阀、球阀和浮球导管等组成。由于浮球导阀、针阀和球阀等是用外接导管与主阀相连接,所以统称为导管控制系统

There are two types of diaphragm type hydraulic remote control floating ball valves: diaphragm type and piston type. The structure consists of a main valve, a filter, a needle valve, a ball valve, and a float tube. Due to the use of external conduits to connect floating ball guide valves, needle valves, and ball valves to the main valve, they are collectively referred to as conduit control systems

序号NO. | 零件名称Name | 主要材质Main Material |

1 | 阀体Valve Body | 铸铁、铸钢、不锈钢Cast lron, Cast steel,Stainless steel |

2 | 密封圈Sealing Ring | 丁晴橡胶Nitrite-butadiene Rubber(NBR) |

3 | 阀板Valve board | 球铁、铸钢Spheroidal Graphite Cast lron, Cast steel |

4 | 螺柱、螺母Plug,nut | 碳素钢Carbon steel |

5 | 小阀板Small Valve board | 铸钢、不锈钢Cast steel,Stainless Steel |

6 | 阀盖Bonnet | 铸铁、铸钢、不锈钢Cast lron, Cast steel,Stainless steel |

7 | 导向套Guide sleeve | 球铁、黄铜Spheroidal Graphite cast lron,Brass |

8 | 阀杆螺母Valve Stem nut | 碳素钢Carbon steel |

9 | 膜片Diaphragm | 丁晴橡胶Nitrite-butadiene Rubber (NBR) |

10 | 膜片压板Diaphragm Pressure Plate | 球铁、碳素钢Spheroidal Graphite Cast lron, Carbon steel |

11 | 导向套螺钉Screw to guide sleeve | 碳素钢Carbon steel |

12 | 膜片座Diaphragm seat | 铸铁、铸钢、不锈钢Cast Iron, cast steel, Stainless steel |

13 | 螺栓Bolt | 碳素钢Carbon steel |

14 | 阀杆Valve Stem | 不锈钢Stainless steel |

15 | 压缩弹簧Compression Spring | 不锈钢Stainless steel |

16 | 阀座Valve seat | 碳素钢、不锈钢Carbon steel, Stainless steel |

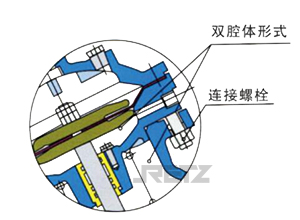

1.为了更有效地防止水锤的产生,水力控制阀将控制室设计成双腔体形式。根据不同的用途可以将两个腔室彼此隔离或相通,以实 现缓开、缓闭或速闭等辅助功能。在一定程度上阻碍水锤的产生或功缓解水锤的力度,保护阀后的其他设备不受损坏。除此之外,阀盖与上腔室连为一体,使得阀盖、上腔室、阀杆、阀盘成为整体,只要松开阀体上的连接螺栓,即可将其一并取出,方便维修及更换易损件。

现缓开、缓闭或速闭等辅助功能。在一定程度上阻碍水锤的产生或功缓解水锤的力度,保护阀后的其他设备不受损坏。除此之外,阀盖与上腔室连为一体,使得阀盖、上腔室、阀杆、阀盘成为整体,只要松开阀体上的连接螺栓,即可将其一并取出,方便维修及更换易损件。

In order to more effectively prevent the generation of water hammer, the hydraulic control valve designs the control room in a dual chamber form. According to different purposes, two chambers can be isolated or connected to each other to achieve auxiliary functions such as slow opening, slow closing, or quick closing. To some extent, it hinders the generation of water hammer or alleviates the force of water hammer, protecting other equipment behind the valve from damage. In addition, the valve cover is connected to the upper chamber as a whole, making the valve cover, upper chamber, valve stem, and valve disc a whole. As long as the connecting bolts on the valve body are loosened, they can be taken out together for easy maintenance and replacement of vulnerable parts.

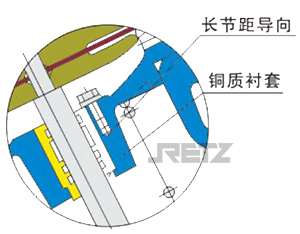

2.隔膜式水力控制阀阀杆两头导向的结构,采用中段长节距导向,避免了阀盖和阀座上的导向孔因加工或安装不同心,导致阀杆运 动受阻、易卡死现象,中段导向套与上阀体整体浇铸,加工精度得到保证,同时在与阀杆的接触面间加一铜质衬套,保护阀杆表面不被磨损、擦毛,使阀杆运动自如、平稳、灵活。

动受阻、易卡死现象,中段导向套与上阀体整体浇铸,加工精度得到保证,同时在与阀杆的接触面间加一铜质衬套,保护阀杆表面不被磨损、擦毛,使阀杆运动自如、平稳、灵活。

The structure of the diaphragm type hydraulic control valve stem is guided at both ends, adopting a mid section long pitch guidance, which avoids the phenomenon of the valve stem movement being blocked and easily stuck due to uneven machining or installation of the guide holes on the valve cover and valve seat. The mid section guide sleeve and upper valve body are cast as a whole, ensuring machining accuracy. At the same time, a copper sleeve is added between the contact surface with the valve stem to protect the surface of the valve stem from wear and burrs, making the valve stem move freely and smoothly flexible

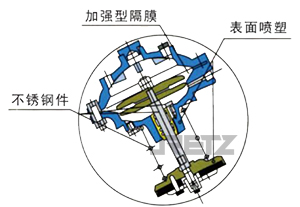

3.隔膜式水力控制阀的阀盖、上腔室、阀杆、阀盘可整体取出,方便维修及更换橡胶密封面、O形环等易损件。阀盖与上腔室之间 的隔膜采用尼龙网布加强型橡胶隔膜,耐剪切应力使用安全可靠。内件包括上腔式、阀杆、阀盘、弹簧、螺栓等,除了不锈钢件以外都进行了无毒喷塑处理,具有良好的防腐性能。

的隔膜采用尼龙网布加强型橡胶隔膜,耐剪切应力使用安全可靠。内件包括上腔式、阀杆、阀盘、弹簧、螺栓等,除了不锈钢件以外都进行了无毒喷塑处理,具有良好的防腐性能。

The valve cover, upper chamber, valve stem, and valve disc of the diaphragm hydraulic control valve can be taken out as a whole, making it convenient for maintenance and replacement of vulnerable parts such as rubber sealing surfaces and O-rings. The diaphragm between the valve cover and the upper chamber is made of nylon mesh reinforced rubber diaphragm, which is safe and reliable for shear stress resistance. The internal components, including the upper chamber, valve stem, valve disc, spring, bolt, etc., have undergone non-toxic spray molding treatment except for stainless steel parts, which has good anti-corrosion performance.

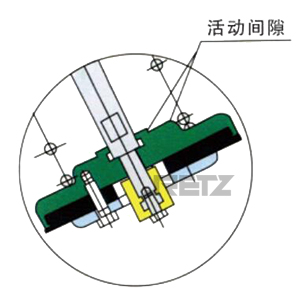

4.隔膜式水力控制阀的阀盘采用间隙组合结构,即阀杆和阀盘孔之间有一定的间隙;阀盘用螺钉和挡块相对固定在阀杆之间并留有 1-2毫米间隙,这样阀盘在垂直于阀杆的平面上有一定的自由度,可以弥补由于加工或装配误差造成阀座密封面与阀杆不垂直的缺陷,实现了零泄漏

1-2毫米间隙,这样阀盘在垂直于阀杆的平面上有一定的自由度,可以弥补由于加工或装配误差造成阀座密封面与阀杆不垂直的缺陷,实现了零泄漏

The valve disc of the diaphragm hydraulic control valve adopts a clearance combination structure, that is, there is a certain gap between the valve stem and the valve disc hole; The valve disc is relatively fixed between the valve stem with screws and stop blocks, leaving a gap of 1-2 millimeters. This allows the valve disc to have a certain degree of freedom in the plane perpendicular to the valve stem, which can compensate for the defect of the valve seat sealing surface not being perpendicular to the valve stem due to machining or assembly errors, achieving zero leakage.

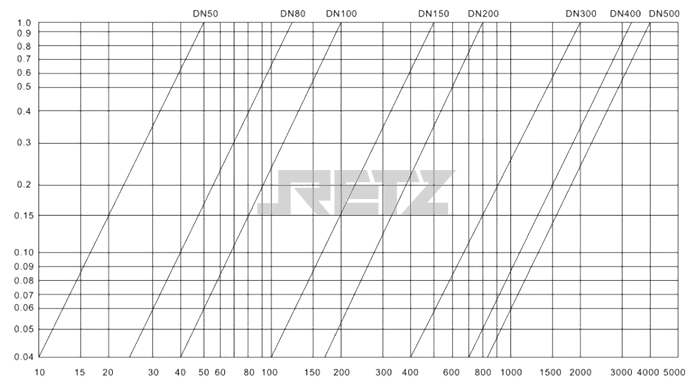

基本流量压差特性曲线图(Basic Flow and Differential Pressure Characteristic Graph)

安装与调试

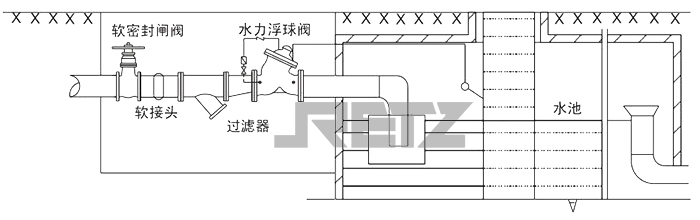

1、主要安装于水池或高水位水塔的管道上,最佳安装方式是水平安装在管线上,阀盖朝上,其它安装方式也可达到操作功能。浮球安装于水池或水塔内,以便遥控。

2、安装前要清除管内杂物,冲洗管道。安装时要注意主阀体外水流标示箭头,要遵循方向安装。

3、主阀前要装一直闸阀和一只过滤器,主阀后也要装一只闸阀,以便于维修。

4、试水时要慢慢开启主阀前的闸阀,慢慢增加压力,同时注意阀体外的控制管路是否漏水。关闭球阀14时,主阀应能关闭,如果主阀不能关闭,检查主阀密封面,可能夹有赃物,将阀盖和带膜片阀杆拆卸,清除赃物即可试水。

5、为出厂时包装方便,浮球阀装于主阀上。

6、主阀导管进口处的微型过滤器要2-3个月清洗一次

在线客服

在线客服